DJC.COM

September 12, 2007

A beautiful tomorrow for structural engineering?

Magnusson Klemencic Associates

Magnusson

|

As ACEC Washington celebrates 50 years of incredible engineering accomplishments, it might also be interesting to gaze into the future. Past advances in structural engineering are visible and well documented, but the future raises many questions.

What materials will be used to construct the buildings of tomorrow? How will the profession respond to the shortage of engineering graduates? How will the entire building industry find new efficiencies through structural engineering? How will advances in computer technology move the profession?

Future construction materials

Over the past 50 years, the typical strength of structural steel has increased 40 percent, reinforcing bar by 50 percent, and concrete by as much as 100 percent. These increases will continue.

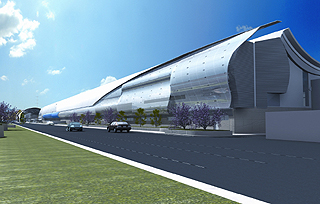

Image courtesy of Grant Architects Complex geometries of both exterior and interior elements will provide a futuristic setting for exhibit display at the new LeMay Automotive Museum in Tacoma.

|

Concrete reinforcing bars, which typically have a strength of 60 ksi, are now starting to be substituted in limited applications with bars having strengths of 75 ksi and even 100 ksi. These higher-strength bars will be used much more frequently in the future because in most applications, the tonnage of rebar needed for a particular building decreases in direct proportion to the increase in strength.

The technology already exists to dramatically increase the common concrete strengths of today, but use of this advanced material is often hampered by the congestion caused by the amount of rebar needed to reinforce it. However, stronger rebar takes up less volume, which results in less congestion so stronger concrete can be used. Expect to see typical concrete strengths in columns and shear walls increase by 100 percent.

Structural steel strengths will also increase for columns and truss members. There have already been very limited uses of steels as strong as 100 ksi, double the 50 ksi common today, and these stronger materials will find increased applications in the years ahead.

Lastly, many new kinds of products will be developed to offer increased sustainability, economy, fire-resistance and/or durability. For example, within the last year, translucent concrete has been introduced. It uses a glass aggregate to allow light to pass through the material. Say goodbye to the expression “solid as concrete”!

Future structural engineers

Image courtesy of Gensler Sweeping steel and glass structures create the architectural form for the new San Jose Airport North Concourse. |

There is a severe shortage of structural engineers throughout the country. While our colleges and universities are turning out many high-quality graduates, there are simply not enough of them.

When I graduated from the University of Washington a little more than three decades ago, there were no female structural engineering graduates. Today, the employment candidate pool is almost 30 percent minority and female. With continuing efforts, tomorrow’s engineers will be far different than the legions of white males of 50 years ago. Any student, from any background, considering a career in structural engineering can be confident of excellent opportunities in the years ahead.

Is off-shoring of engineering services an answer to the engineer shortage? I don’t think so. Today’s structural engineers are problem solvers who work side-by-side with other engineers, architects, owners and contractors to help create buildings. Engineers need to be physically present. They are not simply “beam sizers,” but idea contributors.

The repetitive calculations that might be done by overseas labor resources have already been “outsourced” to in-house high-powered computers. It is not likely off-shore engineering will have a significant role in the future of building structural engineering here.

Future technology

The computer used to perform the structural engineering of the World Trade Center Towers in New York City in the 1960s was the most powerful that had ever been used for building design. The device was the size of a refrigerator and had 16 Kb of RAM. Yes, Kb, not Mb! It’s not possible to even buy a computer with such small memory today.

Here is a view of the future of technology in a combined quote from the pages of Engineering News-Record magazine: “The system’s base graphic system is fully three-dimensional. Whether you’re an engineer or an architect, you interact with the system in exactly the same way; you’re working with a standard command language. Users are able to reuse the same database created in the design stage right through to the construction phase, creating design drawings, construction drawings, quantity takeoffs and other documents. We think that it is faster, better, cheaper.”

Is this a description of BIM? No, it’s IBM. Specifically, the system was a combined effort of IBM and A/E firm Skidmore, Owings and Merrill, and the quote is from 1987. The product being offered was actually an early version of BIM (building information modeling) and sold poorly. Why has it taken 20 years for this approach to start to find industry adoption? First, the power of hardware needed to increase and the cost decrease, both of which have happened. Next, the software needed to be more robust and user-friendly to generate the model information. This is happening now.

Finally, the project delivery process needs to be reinvented to take full advantage of the building database from “cradle to grave.” This is just starting. The American Institute of Architects, Associated General Contractors, and the building owners’ group Construction Users’ Roundtable have formed a cooperative effort called 3xPT to do just that.

At a major workshop in Chicago this summer, 3xPT brought together 45 owners, contractors, subcontractors, architects, engineers, insurance and surety representatives, and lawyers to study current delivery methods including design-bid-build, GC/CM and design-build. The conclusion was that none of these methods can achieve “integrated delivery” without significant change.

One of the most important changes suggested for the future is to include subcontractors very early in the design process to work alongside the A/E team. This will probably require subcontractor selection on the basis of qualifications and track record with a later negotiation of price. I believe this will become a common delivery method in the future. If an owner is uncomfortable with negotiating subcontracts, or prevented by law from doing so, the most likely outcome will be two building information models. In this case, a design BIM will be prepared by the A/E team and an independent construction BIM will be prepared by the contractor team.

Future building designs

Probably the most significant change will be in the geometries that architects will be able to incorporate in design and, just as importantly, that contractors will be able to build efficiently.

The design for Frank Gehry’s Experience Music Project occurred 10 years ago but, thanks to the support of Paul Allen, it is an excellent example of what can and will be done in the future. That’s not to say that buildings will look like EMP, but curving geometries and full integration of the project design and construction, including design databases that literally control the contractors’ fabrication equipment, will be common.

Many building forms that have been considered impossible or too expensive will become mainstream. Two current examples of this new geometric freedom are the San Jose International Airport North Concourse expansion by Gensler and the LeMay Automotive Museum in Tacoma by Grant Architects.

Thinking about the materials, engineers, technology and designs of the future brings to mind the title and lyrics of the theme song at the Carousel of Progress exhibit that was developed by Disney for the 1964 New York World’s Fair: “There’s a Great Big Beautiful Tomorrow.” Absolutely.

Jon Magnusson, PE, SE, Hon. AIA, is chairman/CEO of Magnusson Klemencic Associates, a civil and structural engineering firm founded in Seattle in 1923. MKA has provided engineering services in 46 states and 44 countries.

Other Stories:

- 7 Engineering Wonders: Structural — How to keep it all working after the BIG ONE

- Infrastructure: out of sight, out of mind?

- Engineering a sea change at the aquarium

- ACEC says ‘yes’ to roads and ‘no’ to lawsuits

- Engineers, architects join forces on public policy

- Is our engineering rank slipping in the world?

- 7 Engineering Wonders: Electrical/Communications — Engineering a hospital to save lives

- 7 Engineering Wonders: Mechanical — EMP: an experience unlike any other

- 7 Engineering Wonders: Environmental — Brightwater planning raises awareness, not eyebrows

- 7 Engineering Wonders: Transportation/Infrastructure — Tunnels keep traffic flowing out of sight

- 7 Engineering Wonders: Civil — Making the grade for a road separation

- 7 Engineering Wonders: Geotechnical — A firm foundation for the new Narrows Bridge

- Geotechnical engineering gets a tech boost

- Finding workers may be engineering’s biggest challenge

- ACEC members pick the best of 50 years

- What a difference 50 years make

- What makes engineers tick?

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.