|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

May 16, 2014

Construction Award -- Technology excellence

Turner Construction

|

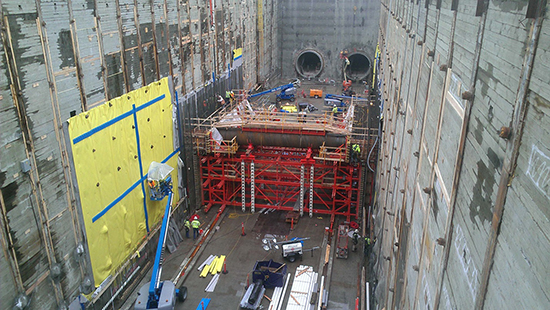

An innovative traveler system was used at Capitol Hill light-rail station by Turner, which self-performed the project’s concrete package.

The system allowed Turner to travel the entire length of the station box, pouring concrete in complete areas. The design team believed eight pours would be required per section to get from the ground level to the roof. The traveler system enabled the team to reduce the total number of pours from 216 to 108, with the truss system spanning the station interior and pouring walls on both sides simultaneously.

This innovative system resulted in time savings by using a five-man crew for a scope of work that would traditionally need a peak crew of 12 men. The system also eliminated the need for shoring towers, allowing other trades to work unencumbered.

Ultimately, over 29,000 cubic yards of concrete were placed by Turner’s crew. The formwork system significantly decreased the project’s schedule and cost while increasing safety and efficiency.

Other Stories:

- GRAND AWARD CONSTRUCTION

Private building $50 million-$100 million - Subcontractor: Safety

Under 250,000 hours - Subcontractor: Safety

250,000 - 400,000 hours - Subcontractor: Safety

Over 400,000 hours - Subcontractor: Safety

Most improved - General contractor: Safety

Under 150,000 hours - General contractor: Safety

250,000-300,000 hours - General contractor: Safety

[TIE] 150,000-250,000 hours - General contractor: Safety

[TIE] 150,000-250,000 hours - General contractor: Safety

Over 300,000 hours - General contractor: Safety

Most improved - Superintendent of the Year

- Brian Salsgiver Safety Professional of the Year

- Construction Award -- Highway and transportation

- Construction Award -- Heavy/industrial

- Construction Award -- Tenant improvement

Over $5 million - AGC/Moss Adams Service to the Community Award

- GRAND AWARD SAFETY

Construction manager: Safety

Under 100,000 hours - Construction Award -- Public building

Under $10 million - Construction Award -- Public building

$10 million-$25 million - Construction Award -- Public building

$25 million-$50 million - Construction Award -- Public building

$50 million-$100 million - Construction Award -- Public building

Over $100 million - Construction Award -- Private building

Under $10 million - Construction Award -- Private building

$10 million-$25 million - Construction Award -- Private building

$25 million-$50 million - Construction Award -- Private building

Over $100 million - Construction Award -- Tenant improvement

Under $5 million - Project Manager of the Year