Surveys

DJC.COM

June 28, 2007

Why integrated design is off to a slow start

Tetra Tech/KCM

Llona

|

Pacific Northwesterners are famous for being green. We’re eager to recycle. We seem to have more LEED-certified professionals per square mile than lawyers. So how do you explain our reluctance to practice one of the most eco-friendly ideas in the architecture/engineering world, namely integrated design?

Integrated design (ID) is architectural and engineering consultants collaborating at the outset of a project, before schematic design, to cut energy consumption as much as possible. The energy model helps determine the shape, heating, cooling, ventilation, lighting, envelope, glazing and orientation of the building. For instance, on a recent project at the University of British Columbia, the shape of a life science building was determined from the results of energy modeling.

The ID concept is hot in the A/E industry. People talk about it at national conferences, emphasizing its importance for “net zero” buildings, or structures with no energy requirements. Yet it’s not happening frequently — not even in progressive areas like Puget Sound.

Cursed with blessings

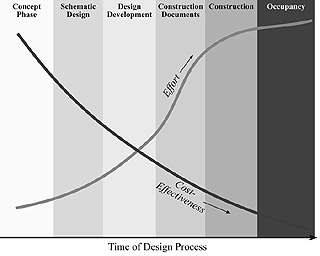

Diagram by Tetra Tech/KCM Energy-saving strategies are easiest to implement early in the design process. As the design progresses, opportunities for energy savings diminish and the effort required to implement them increases. [enlarge] |

One of the biggest reasons we’re not seeing much ID in Washington or Oregon has to do with our favorable energy rates, which are among the lowest in the nation. We’re blessed with guaranteed hydroelectric power, at prices kept down through historic agreements between utilities and the government.

Also, there’s our relatively mild climate. It rarely gets below freezing, and our annual heating requirements are less than most of the rest of the nation. Neither do we need air conditioning most of the year, since we spend most of our summer hours in the 60- and 70-degree temperature range.

Combining these two factors gives you energy costs that are too low to push major conservation initiatives like ID. Sure, we kick and holler about prices rising. But we’re living in the lap of luxury compared with people in the harsh, coal-dependent Northeast.

Distinct budget buckets

Since ID is still not widely accepted in colder regions either, we must consider drivers other than energy costs. One of these has to do with the way that buildings are paid for. Traditionally, separate budgets are maintained for design, construction, operation and demolition. Different people oversee each part of the picture and often compete with one another for scarce resources. This is especially true in the public sector, where projects lack a single “owner” with a bird’s eye view on total costs over the lifetime of the building.

The result is that savings in long-term maintenance or energy costs cannot be easily allocated to fund up-front design or construction costs. And ID tends to require more early analytical work than “business-as-usual” designs. So integrated design will probably not really come into its own until projects have integrated budgets.

Selling less “stuff”

Yet another hurdle for ID derives from the tendency to stay with traditional approaches to designing buildings. Currently, consultants specify state-of-the-art, eco-friendly systems to achieve green goals. But these systems are usually expensive. Maintenance crews are unfamiliar with them, making the systems more costly to maintain. In fact, crews frequently disable some of the energy-saving features of systems that they don’t understand, minimizing planned energy savings.

Designing with more and better “stuff” might get you LEED certification, but it also takes more energy to manufacture and install. This can result in a larger overall carbon footprint, which contributes to continued global warming.

A new mind-set

To participate in the integrated design process, many engineers will have to change the way they think. We’re conditioned to work in a linear fashion, coming up with heating and cooling designs only when we know what the building will look like. Give us a box, and we’ll design the systems for you.

ID calls for a more creative approach, where engineers contribute to the shape and positioning of the box itself. We must learn to put our cart before the horse, assessing the potential impact of systems on an as-yet-unidentified structure. This moves us away from a focus on “stuff” to a new emphasis on end-to-end functionality. Architects already do this, to some extent. They can add even greater depth to the process with practical insights from mechanical engineers.

ID’s triple bottom line

Integrated design seeks to reduce all these factors by looking at a triple bottom line. Today, we care mostly about the economic bottom line. ID, on the other hand, urges us to consider social consequences and environmental equity as well. Only when all three are given equal weight have we achieved true sustainability.

For example, imagine a new office building going up. Engineers and architects confer at the beginning of the project, creating basic energy models on preliminary designs. They discover that by rotating the structure slightly on the site they can take advantage of direct sunshine on one face of the building for lighting and fresh breezes for ventilation on another. Energy costs will go down, as will pollutants from heating and cooling operations. Also, worker productivity will go up because employees are more comfortable, an effect documented in numerous studies. There’s your triple bottom line.

The good news is technology makes energy modeling fast and inexpensive. Most architects guess that an energy model will cost about one third of the engineer’s fee — which it may have in the old days. Not today. We can prepare a meaningful model in about four hours. This gives the architect a better way to inform the building’s design, comparing various approaches to the building’s envelope, glazing and overall function — for better long-term resource conservation.

Joe Llona is a senior mechanical engineer at Tetra Tech/KCM in Seattle.

Other Stories:

- Cleaning up stormwater runoff on freeways

- New Seattle hotel to marry luxury with green

- Lakehaven solves water woes with ASR

- Treating rural wastewater is a daunting task

- The Emerald City’s tourist industry turns green

- Are nanomaterials another environmental worry?

- Tribe’s waste plant doesn’t raise a big stink

- When BMPs can’t meet stormwater permit rules

- Contaminated site? Let Mother Nature help

- Study your options when banking or reserving wetlands

- Developers must dodge newly discovered fault hazards

- A solution to our dwindling water supply lies below

- What to know when buying a contaminated site

- Blending a new community into the environment

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.