|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Environment

| |

|

February 27, 2014

U.S.-Mexico border crossing gets a net-zero makeover

Miller Hull Partnership

Misel

|

The San Ysidro Land Port of Entry between San Diego and Tijuana, Mexico, is the busiest border crossing in the world. Almost 20 million people cross the U.S.-Mexico border at San Ysidro every year, making the efficiency of the port an important driver of the regional economy.

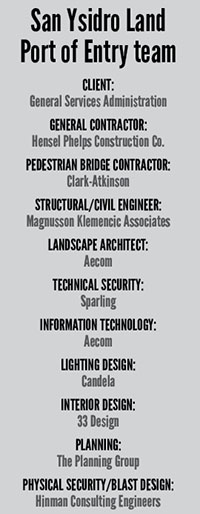

The Miller Hull Partnership has designed a new border station at San Ysidro for the General Services Administration to be completed in three phases, comprising a total renovation, modernization and expansion of the 40-acre facility. One of the largest GSA construction projects currently under way, the $577 million effort also targets zero net energy in all occupied spaces.

A U.S. milestone

Our firm has experience designing high-performance buildings, yet the scope and scale of this design opportunity in an extreme climate pushed our creativity to a whole new level.

If constructed as planned, project will become the first facility open 24/7/365 to achieve a zero net energy milestone in the United States. And it sets an impressive example for other projects to follow in moving toward a presidential executive order mandating that all federal construction projects completed in 2020 and beyond must be zero net energy by the year 2030.

The first phase of construction is scheduled for completion by 2015. Primary goals of the overall project are to reduce wait times for the traveling public and to provide security and technological enhancements for the U.S. Customs and Border Protection (CBP) employees who process approximately 50,000 vehicles and 25,000 pedestrians per day.

In addition to providing civil roadwork to accept a larger number of vehicles, the current phase of construction offers two new inspection canopies to shade employees from sun and glare, and provides the port with a 90,000-square-foot administrative and operations building.

The GSA’s current sustainability standard for new construction is LEED silver. During design, Miller Hull pushed GSA and CBP to consider setting a new bar for international border crossings worldwide, both operationally and for high performance.

It is expected that all three construction phases will likely be complete before 2020, but with our integrated design process and approach, we were able to establish goals that enable the project to achieve LEED platinum through energy-efficiency and water-conservation strategies. On the energy side, a 12.3 million-kilowatt hour photovoltaic system, combined with solar thermal panels and a geothermal cooling and heat sink system, do most of the heavy lifting.

Conserving stormwater

In San Diego, where average rainfall is just 11 inches each year, water shortages and drought make the conservation, collection, treatment and reuse of water one of the most compelling objectives for the port. For this reason, the first phase of the project also includes a 290,000-gallon subgrade water cistern, helping the port conserve and reuse as much water as possible.

During design, we worked with Magnusson Klemencic Associates and Interface Engineering to account for every drop of water entering the site.

Stormwater from 8.5 acres of new elevated canopy, building roof and plaza is collected and routed to the cistern. The cistern provides a means to capture and reuse all collected surface water in a secondary graywater piping system installed in each building on site, and provides for non-potable water uses such as toilet flushing, irrigation and maintenance.

In addition to on-site collection, hydrology maps indicated it would be necessary to capture and accommodate 282 acres of surface water runoff from adjacent hillsides. As a result, the cistern was sized to optimize use during both rainy and sunny months of the year.

Even in San Diego the cistern overflows during rainy months. To mitigate this, bioswale planters capture and treat surface water runoff and overflow from the cistern. While the site infiltration rate varies across the 40 acres, the project’s bioswales allow for treatment and infiltration instead of immediate release into the adjacent Tijuana River and Estuary. A large bioretention/infiltration basin installed along the border fence ensures the port of entry will be a net-zero stormwater runoff site.

An important issue we recognized during design is that while the cistern provides for the graywater system during rainy months, it is essentially empty from May through November. To be viable, the cistern requires a source of makeup water. We investigated using reclaimed water through a new “purple” reclaimed-water pipe from the nearby San Diego South Bay water treatment plant to provide makeup water to the cistern, but it did not pencil out.

Water treatment

The one consistent project water source is black/gray water from toilets, showers and condensate. In fact, there is quite a lot of it due to continual use by CBP officers and the traveling public visiting site buildings every day. Treatment of blackwater with the use of an on-site hollow tube membrane bioreactor was determined to be a viable and efficient solution to the makeup water issue.

Our life-cycle cost analyses for the membrane bioreactor demonstrated a long-term savings of water/sewer costs for GSA and a 19-year payback. Membrane bioreactors are highly efficient — 81 percent of the treated water can be reused, reducing the load on the city’s sewer system. With the membrane bioreactor as a source of makeup water, the cistern is usable every day of the year for graywater needs and as a geothermal cooling and heat sink.

Using these water-conservation strategies — the cistern/membrane bioreactor system, bioswales and bioretention/infiltration basins — will allow GSA to conserve 28 million gallons of water per year, including reducing potable water use by 12.1 million gallons of water per year. By 2030, the port of entry will be able to boast a 78 percent overall water reduction, a sewer use reduction of 99 percent, and provide net-zero (100 percent) non-potable water and stormwater runoff.

The aggressive energy- and water-efficiency goals achieved through both active and passive systems maximize system efficiency and will greatly reduce operational costs for the life of the port. Our team is honored to be part of GSA’s efforts to lead by example, demonstrating good stewardship of available resources through sustainable design, which at San Ysidro Land Port of Entry, is especially true for water, one of San Diego’s most precious resources.

Rob Misel is a principal at The Miller Hull Partnership and serves as project manager for the San Ysidro Land Port of Entry project.

Other Stories:

- Investing in green spaces can pay off for property owners

- LEED vs. Green Globes: How to choose

- How transparency can change the game on green building

- LEED shifts focus from design to performance

- LEED is here to stay so long as owners find it useful

- Old warehouse now a super-efficient office building

- King County to try new rating system for infrastructure

- Historic rehab a test for performance-based codes

- Stone34 to put its deep green bona fides to the test

- No guts, more glory: Why it pays to go minimal

- State seeks to wring more value from its projects