Surveys

AIA Awards

DJC.COM

November 20, 2003

Water tower repairs borrow on building technology

Reid Middleton

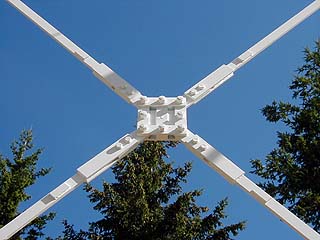

Both the Rolling Hills, top, and Highlands elevated water tanks were fortified following the Nisqually earthquake of 2001.

|

Structural engineers faced a retrofit challenge after two Renton-based elevated water tanks were damaged during the Nisqually earthquake. How can the necessary structural repairs be used to seismically upgrade these lifelines with minimal extra cost? And what earthquake engineering standards should be applied to these non-building structures?

Elevated water tanks are rare, and the most current seismic evaluation and retrofit guidelines focus on buildings, not on elevated towers that carry an unusually heavy top weight. What resulted was a careful extrapolation of building-related guidelines, which innovatively permitted performance-based engineering concepts to be applied to these non-building structures.

Nisqually damage

The city of Renton owns two elevated water tanks, which are located in the Highlands and Rolling Hills districts. These 30- and 40-year-old tanks are essential structures that supply drinking and fire fighting water to more than 40 percent of the city's population of 55,000.

The magnitude 6.8 Nisqually earthquake in 2001 damaged both tanks. Reid Middleton, a subconsultant to Redmond-based GeoEngineers, was called in to observe the damage and perform a comprehensive seismic evaluation of each tank.

Damage to the tank structures consisted of spalled base plate grout, sagging and kinked radial rods, and an excessive number of buckled steel diagonal braces. A seismic repair and retrofit scheme was implemented to restore and enhance the capacity of the tank structures to resist earthquake motion.

The structural evaluation involved analyzing the existing tanks and determining concept retrofit alternatives. To do this, Reid Middleton combined its civil- and industrial-related knowledge with its experience in seismically retrofitting buildings throughout the Pacific Northwest and Alaska.

Standards used

Seismic evaluation and concept retrofit design was performed using the following standards:

- AWWA D100 (American Water Works Association, 1997).

- 1997 Uniform Building Code (International Conference of Building Officials, 1997).

- FEMA 356 Prestandard and Commentary for the Seismic Rehabilitation of Buildings (Federal Emergency Management Association, 2000).

Each standard has a different combination of hazard level and performance objective. FEMA 356 was chosen over the AWWA standard that has been customarily used for seismic design of tank structures. This approach allowed Reid Middleton and the city to use newer technologies and achieve a higher level of expected seismic performance.

A traditional repair and retrofit approach would have included replacing the entire bracing structure of the tanks — a very costly endeavor. In fact, subsequent analysis revealed that the costs to retrofit the tanks using conventional strengthening and stiffening methods were about 50 to 80 percent of the cost to replace the tanks.

The Highlands Reservoir was constructed in 1960. Its 750,000 gallons of water rest 135 feet above grade. The welded round steel tank is 66 feet, 6 inches in diameter and 42 feet, 6 inches in height at its center. It is supported by a 72-inch-diameter riser column and eight 48-inch-diameter pipe columns equally spaced around the perimeter at a 32-foot, 3-inch radius.

The Rolling Hills Reservoir was constructed in 1970. Its 300,000 gallons of water rest 115 feet above grade. The tank is 45 feet in diameter and 30 feet in height at its center. It is supported by a 48-inch-diameter center column and five 36-inch-diameter steel pipe columns equally spaced around the perimeter at a radius of 28 feet. Each perimeter column has a constant wall thickness of .406-inch.

Analytical steps

During an earthquake, tension in one brace will force the plate in the damper to slip. In response, the damper shortens the other brace and keeps the tank’s frame from buckling.

|

Three-dimensional finite element models were developed in SAP 2000TM (Computers and Structures Inc.) using the existing member sizes and assumed material properties. The first step involved a series of simple static and dynamic analyses using each of the previously noted standards. The results obtained from each standard were cross-compared and set the basis for determining the retrofit strategy and the appropriate design criteria.

Nonlinear dynamic analysis of the tanks was then performed using records from past earthquakes, modified to the specific earthquake hazards and soil conditions of the sites. The impacts of the sloshing water in the tank were incorporated into the model. A series of 60- and 70-kilopound friction dampers, used in conjunction with the existing braces, were determined to provide the optimal upgrade solution for the tanks.

Friction dampers

By July 2003, the tanks were repaired and seismically upgraded using friction dampers manufactured by Pall Dynamics. Using dampers cost 35 percent less than the price of using conventional seismic strengthening methods, which would have involved replacing the tank braces with larger steel braces and costly foundation upgrades.

The passive energy dissipation devices were evaluated using site-specific time history records for both 475- and 2,475-year seismic events. The benefit of friction dampers lies in their simplicity — they absorb energy. Just as an automobile's brakes take energy away from its movement, the dampers control the motion of a vibrating structure by absorbing earthquake energy.

A friction damper consists of a series of plates that are clamped together with high-strength bolts. During an earthquake, the dampers absorb energy and generate heat through the rubbing of the plates much like a person rubbing their hands together generates energy in the form of heat.

Six other elevated tanks in the United States have been retrofitted using friction dampers. Only one tank has been larger.

Dave Swanson, PE, SE, is director of structural engineering at Reid Middleton.

Other Stories:

- Today's buildings load up on technology

- Letting rainwater reign in the design process

- Church praises the benefits of adaptive re-use

- UW builds on design leadership training

- Science studies how architecture affects the brain

- China creates a park with environmental appeal

- How the Great Fire changed Seattle's architecture

- Architects play catch-up in the business world

- Designing with nature in the balance

- 12 keys to creating authentic people places

- Monorail to move urban design as well as people

- Technology takes center stage in performance halls

- In hospitals, spending more can save money

- Don't be violated — protect plans with copyrights

- Special dampers may shake up engineering field

- UW Allen Center fosters a culture of research

- Here's why projects need to be commissioned

- Unwrapping modern building envelopes

- Lessons on sustainability, Scandinavian style

- Building a highrise on the fault line

- How to keep development from killing trees

- Rx for changing healthcare industry: Good design

- Muckleshoot project blends culture with design

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.