|

Special applications: Technical merit |

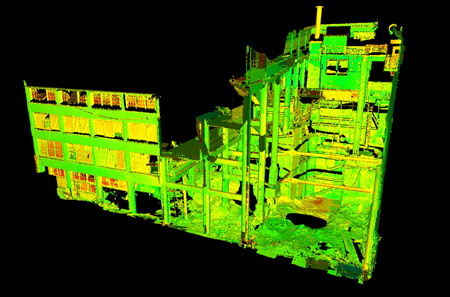

Image courtesy of WACA

Three-dimensional modeling and laser scan technologies were used at Pike Place Market during pre-construction to record conditions and build a design prototype. The model was used to estimate materials such as concrete and rebar.

Pike Place Market, Phase 1 |

|

Location: Seattle

|

|

The Pike Place Market renovation involves a series of phased projects aimed at upgrading the structural and mechanical performance of its infrastructure. Included in the project was a new Seattle City Light vault hidden from public view in a structure designed to maintain the marketís century-old character. Three-dimensional modeling and laser scan technologies were used during pre-construction to record conditions and build a design prototype. The resulting model was used to define scope and estimate materials, including concrete, rebar, structural excavation, backfill and formwork. Temporary and permanent shoring supports were required to excavate the 7,200-square-foot site to a depth of over 50 feet. Top-down soil nails were used to support approximately 20 feet of excavation required under the existing elevator. Existing column footings, which supported occupied public areas above, were undermined and resupported using drilled micropiles filled with high-strength grout. Shotcrete was used for unexposed walls wherever possible in order to ease installation around internal shoring bracing. High-strength performance concrete poured into hand-set forms was used at the new elevator shaft shear walls. Caltite concrete was used on top of the new electrical vault as part of a value-engineering solution, eliminating the need for secondary waterproofing. This allowed the early placement of the City Light transformers. Multiple lifts of controlled density fill were used as structural backfill instead of the specified soil backfill, easing placement and improving safety. All exposed walls required a board form finish to match the adjacent buildings. Careful placement of concrete eliminated the need for tie hole patching, improving the appearance of the finish.

|

|

Copyright ©2011

Seattle Daily Journal and DJC.COM. Comments? Questions? Contact us. |