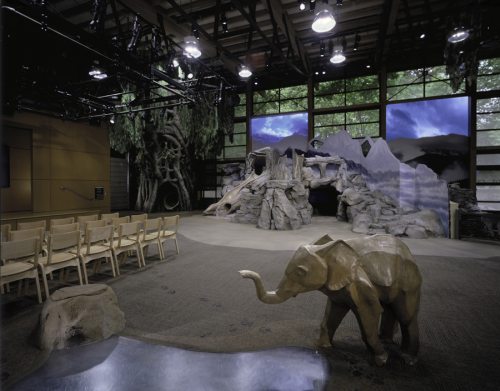

Zoomazium

Architect: Mithun

Owner: Woodland Park Zoo

ABC members: Artistic Drywall Textures, Audio Acoustics, Bratrud Middleton Insurance, Kibble & Prentice, Mastercraft Electric, Northshore Paving

Woodland Park Zoo’s Zoomazium is an 8,500-square-foot environmental learning and play space for young children.

Kirtley-Cole took many measures to ensure the project would earn LEED gold certification, including recycling more than 93 percent of the construction waste, which diverted more than 33 tons of waste from local landfills.

The team carefully addressed scheduling, as acquiring environmentally sound materials often meant long lead times. For example, the Forest Stewardship Council-certified glu-lam beams, trusses and columns had a 16-week lead time. The wood also was oversized, which limited delivery times.

The Zoomazium roof has curved lines formed by the support system of steel and wood-beam trusses, allowing the eye to follow a natural line to and from the surrounding forest. More than 70 percent (by cost) of the project’s wood-based materials were produced from wood obtained from forests managed in an environmentally responsible manner.

The green roof displaces the water runoff caused by the structure’s footprint, in essence moving the forest floor upward. The curve of the roof also supports an intricate roof membrane and drainage system beneath 6 inches of topsoil that is planted with nearly 21,000 native plants.

The windows are fritted with small dots, which appear clear from the inside and white from the outside. They are an attempt to keep birds from flying into them and to diminish the obstacles a building presents to the surrounding environment.

A building management system automatically controls the upper windows and indicates when lower windows should be manually opened or closed. The lighting system includes energy-efficient fluorescent lights, theatrical lights for the stage area and occupancy sensors in offices.

Some unique project challenges were keeping the free-roaming peacocks off the site, especially during concrete pours, and watching noise levels to protect nearby incubating eggs and lemurs that were giving birth. Also, the root zone of a stand of prized trees was protected. Workers were often called upon to modify their activities around previously planned zoo events.

The $2.95 million project was built in just over seven months, with no injuries in 8,763 hours worked.