Awards

DJC.COM

May 3, 2002

The riddle of ancient Roman concrete

Retired civil engineer

Editor’s note: This article first appeared in “The Spillway,” a newsletter of the U.S. Department of the Interior, Bureau of Reclamation, Upper Colorado Region, February 1993.

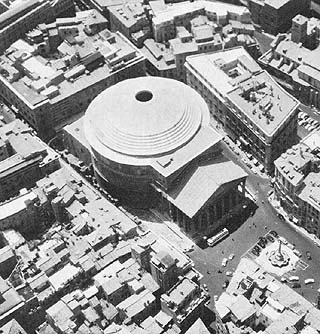

The Pantheon in Rome has stood for over 1,800 years — without steel reinforcement. |

Ancient Roman concrete has withstood the attack by elements for over 2,000 years.

The basic construction techniques of the Romans must be equal or better than those of modern practice as judged by comparing the products. Can we learn from the Romans in some way to improve our concrete?

Dusty ancient history books teach us that Roman concrete consisted of just three parts: a pasty, hydrated lime; pozzolan ash from a nearby volcano; and pieces of fist-sized rock. If these parts were mixed together in the manner of modern concrete and placed in a structure, the result certainly would not pass the test of the ages.

Moore |

How did those Romans around the time of Christ build such elaborate, ageless structures in concrete as seen on the skyline of Rome?

A most unusual Roman structure depicting their technical advancement is the Pantheon, a brick-faced concrete building that has withstood the ravages of weathering and floods in near perfect condition, sitting magnificently in the business district of Rome. Perhaps its longevity is told by its purpose ... to honor all gods.

Above all, this building humbles the modern engineer not only in its artistic splendor, but also because there is no steel reinforcing to counter the tensile forces in the structure like the way we hold modern concrete together.

Solving the riddle of Roman concrete consisted of two studies: one was understanding its chemistry, and the other was the role that placement had in its strength.

Chemistry

With a 142-foot inner diameter, the Pantheon is said to have the longest span built before the 19th century. |

To understand Roman concrete’s chemical composition, we must go back in time much before Moses. People of the Middle East made walls for their fortifications and homes by pounding moist clay between forms, often called pise work. To protect the surface of the clay from erosion, the ancients discovered that a moist coating of thin, white, pasty lime, would harden to give their walls significant protection from rain and weather.

The pasty lime was created by heating limestone in a kiln and then quenching the result in water. When the lime plaster dries out, the calcium in the material chemically combines with carbon dioxide in the air to give a hard protecting shield. We can only guess that the event of discovering a precursor to Roman concrete probably occurred some 200 years before Christ when one of these lime coatings was applied to a wall made of volcanic, pozzolanic ash near the town of Pozzuoli in Italy.

A reaction took place between the chemicals in the wall of volcanic ash (silica and small amounts of alumina and iron oxide) and the layer of lime (calcium hydroxide) applied to the wall. Later they found that mixing a little volcanic ash in a fine powder with the moist lime made a thicker coat, but it also produced a durable product that could be submerged in water — something that the plaster product of wet lime and plain sand could not match.

To explain this chemical difference we must examine the atomic structure. Common plaster is made with wet lime and plain sand. This sand has a crystalline atomic structure whereby the silica is so condensed there are no atom holes in the molecular network to allow the calcium hydroxide molecule from the lime to enter and react. The opposite is true with the wet lime-pozzolan contact.

The pozzolan has an amorphous silica atomic structure with many holes in the molecular network. Upon mixing the wet lime with the pozzolan, the calcium hydroxide enters the atomic holes to make a concrete gel which expands, bonding pieces of rock together. The fine powder condition of the pozzolan provides a large surface area to enhance chemical reaction.

We find parts of the complex chemistry of the ancient concrete bonding gel matching the same chemical formula of modern concrete bonding gel. And this is so; the pozzolan-wet lime gel gave permanence to the ancient concrete.

Placement

The Pantheon is surrounded by much more modern buildings. |

Explaining the placement of ancient concrete solved the second part of the riddle. Unwittingly, research by the Bureau of Reclamation played a key role here. Chemistry alone will not make good concrete. People make good concrete, and the Bureau of Reclamation has claimed the fame of this expertise.

Although a new concrete product called roller-compacted concrete had been crudely developed, Reclamation’s refinements made it an economical candidate for dam construction. In 1987, the Bureau of Reclamation’s astute engineering force built the large Upper Stillwater Dam made of roller compacted concrete in eastern Utah.

| Band the Pantheon? |

|

There is one remaining question from my technical studies I need help resolving.

The concrete dome of the priceless Pantheon is some 1,800 years old, and in this time, the nearly 43-foot dome has acquired some tension cracks since there were no steel rods in ancient Rome. My contentious question: Should we place steel bands around the outside steps of this dome to assure some protection against the next major earthquake? Let me know what you think. Send me an e-mail at moore.john.e@worldnet.att.net. – David Moore, PE |

This concrete consisted of a mixture of 40 percent Portland cement and 60 percent fly ash, a by product of electric powerplants. By coincidence, the fly ash contained the same amorphous silica compounds as the ash from explosive volcanoes. And the hydrated Portland cement released the calcium component recognized in the lime part of the ancient concrete formula.

When Reclamation mixed these two parts for its dam. a bonding gel was formed to tie inert rock pieces of the hatch together. These rocks were used as a strong filler material much in the same manner as is used in standard concrete practices.

So we can easily relate the calcium hydroxide molecules from the Portland cement to that of the ancient wet lime, and the amorphous silica of the pozzolan fly ash to the amorphous silica of the volcanic pozzolan. Thus, we have established a reasonable relationship for the concrete components that make the gel for both modern and ancient concrete.

Old versus new

The similarity of the ingredients of modern and ancient concrete has been explained, but there is more. Studies of the placement process are very important in making durable concrete.

The Bureau of Reclamation mixed its components (cement, ash and rock) with as little water as possible to give a stiff, “no-slump” concrete; spread it in layers on the dam; and pounded it into place by large vibrating rollers to make a new class of concrete.

The ancients hand mixed their components (wet lime and volcanic ash) in a mortar box with very little water to give a nearly dry composition; carried it to the job site in baskets; placed it over a previously prepared layer of rock pieces; and then proceeded to pound the mortar into the rock layer.

Photos courtesy of David Moore The U.S. Bureau of Reclamation refined the method of roller-compacted concrete and used it in 1987 to build Upper Stillwater Dam in eastern Utah. Romans used a similar technique.

|

Fortunately, we have proof ... Vitruvius, the noted Roman architect (cir. 20 B.C.) mentioned this process in his history formulas for his concrete, plus the fact that special tamping tools were used to build a cistern wall.

Is this important? Yes, close packing of the molecular structure by tamping reduced the need of excess water, which is a source of voids and weakness. But also close packing produces more bonding gel than might be normally expected. Again. we have a similarity in the ancient and roller-compacted concrete practices, which is that of tightly compacting the materials in their placement.

We have learned that ancient concrete was a simple mixture of wet lime and pozzolan in specific ratios to match the desires of the Roman architect. We have also learned that the Romans followed a placement method of tamping their stiff mortar into the voids of a rock layer.

Interestingly enough. the new concrete which has been developed by the Bureau of Reclamation follows closely that of the ancients. So we can readily assume that the new class of concrete in Upper Stillwater Dam will last ... perhaps for 2,000 years like the ancient concrete.

David Moore is a distinguished registered professional civil engineer with more than 45 years of wide-ranging civilian and military work experience. He is the author of “The Roman Pantheon: The Triumph of Concrete” from which much of this material is based. The book can be obtained from his Web site on Roman concrete at www.romanconcrete.com. Moore can be contacted via e-mail at DaveMoore@romanconcrete.com.

Other Stories:

- A solid future for concrete design

- Colored concrete offers an alternative to wood, stone, brick

- You say you want a Revolution?

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.