DJC.COM

November 16, 2006

Complex projects call for virtual construction

Sellen Construction

Condit

|

Technology has become an increasingly important tool in effective project delivery, allowing teams to coordinate seamlessly between systems and disciplines, plan for an efficient construction period and ensure quality workmanship. One tool that is getting recognized for its ability to greatly assist with design and construction is building information modeling.

BIM allows project teams to build projects in a virtual environment before construction ever commences. This technology can be applied to any type of building, but with the complexities associated with medical facilities, BIM is a valuable resource.

Phasing

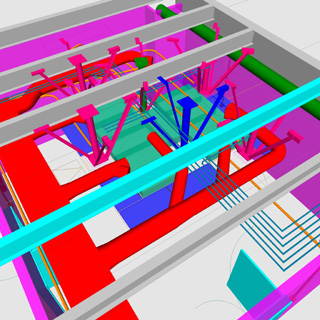

Image courtesy of Sellen Construction Building information modeling can be used to coordinate heavily congested areas such as operating room ceiling spaces. |

When building out interior spaces in an occupied medical facility, BIM can be used to determine the best phasing scheme that minimizes impacts to staff, patients and visitors. Alternate phasing sequences can be evaluated in terms of ingress/egress routes, operational shutdowns, temporary spaces and infection-control procedures.

Using BIM also helps to clearly communicate the construction phasing plan to staff, so they understand what is happening and when. By keeping the people affected by the buildout fully informed, there is less confusion and a positive attitude is promoted about the new facility or renovated space.

Prefabrication

Using BIM to identify opportunities for prefabrication is one area that can result in substantial savings.

For example, on a recent medical project Sellen had to build a utilidor to connect existing services to a new facility. Utilizing the information generated by BIM, racks were built to specification off-site to connect chilled water, electrical services, emergency power and medical gases to the new building. Installing the prefabricated racks allowed the field crews to maintain the aggressive schedule while maintaining the quality of installation.

Virtual room

Another application that can save costs and improve functionality is a virtual mock-up of a room.

For instance, a hospital patient’s room has many features that contribute to the overall well-being of the patient. How does the bathroom layout respond to the location of the bed? How does monitoring equipment relate to outlet locations? What furniture can impede administering medical services?

BIM can be used to test a realistic room layout that allows nurses and doctors to comment on what equipment would work better, what needs to be improved and make other suggestions for enhanced functionality. From this feedback, a physical mock-up can then be constructed to ensure the design meets the needs of the hospital staff and patients.

Medical equipment

One of the biggest challenges on any medical project is the installation of medical equipment.

Three areas in which BIM can help include the identification of long lead items, coordination with existing mechanical and electrical systems, and determination of the best access routes to get the equipment into position.

Integrating the procurement process into the model allows a schedule to be generated, notifying the construction team when items need to be purchased to ensure on-time delivery. BIM also helps with coordinating shutdowns by finding the most viable time with the least impacts upon surrounding operations.

Perhaps the most difficult task is getting the equipment physically into the building — moving a 30,000-pound MRI machine through a corridor requires advanced planning. BIM can be used to find the precise date in the construction schedule and the optimal ingress route to ensure successful installation of medical equipment.

Ceiling access

Working in a hospital environment requires meeting stringent health requirements compared with working in other, less technical facilities. Implementing infection-control measures is extremely vital to protect patients from harmful bacteria, mold and dust.

Since mechanical and electrical systems are usually located in the ceiling, gaining access for construction and maintenance without causing potentially hazardous conditions is critical to ensure patients’ health. BIM provides pinpoint accuracy to locate access points in the ceiling without disrupting infection-control safeguards.

System coordination

Health care facilities have substantially more infrastructure than any other type of facility, making system coordination more imperative.

To prevent conflicts between structural, mechanical, electrical, fire protection and plumbing systems, BIM software has built-in testing tools that help detect clashes. Using a tool that helps automate the detection process allows the team to spend less time finding issues and more time generating solutions.

By working within the virtual building, problems are quickly identified and corrected. For instance, Sellen used BIM’s overlaying capabilities to discover a chilled water pipe intersecting an air vent on a recent medical project. Catching the problem early in the design process allowed the project team to find a solution and prevent costly rework.

Maintenance

A building’s electrical and mechanical systems are essential to the overall success of a building, which is especially true in a medical environment.

Air quality, medical gas lines, electrical load capacity and air volume are part of the systems that create a comfortable, healthy environment. To ensure these systems are working according to their performance criteria, regular maintenance is essential.

BIM integrates maintenance schedules and systems information to provide facilities staff a detailed plan on when filters need to be changed, for example, or how to alter fan speed. By making upkeep as user-friendly as possible, the longevity of systems can be enhanced.

BIM is a highly beneficial tool in hospital construction because it integrates all the complex components involved in building medical facilities.

Knowing how the building’s elements, including systems, schedules, room layout and equipment work with each other reduces costs, requests for information and potential schedule delays. With all of the project information available to be reviewed and analyzed with BIM, it becomes a tool that merges the design intent with the owner’s needs to find the best possible solution.

Graham Condit, director of CAD technologies, works with the preconstruction group at Sellen to identify opportunities for using building information modeling to analyze, solve, and communicate complex construction issues.

Other Stories:

- Hospital gardens help patients heal

- New law encourages hospitals to give patients a lift

- Hotels offer lessons for Oregon hospital

- State to adopt national health care design standards

- Quick! Turn an office building into a medical center

- Build a better building with 3-D modeling

- Boomers shaping future of health care design

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.