Surveys

DJC.COM

June 28, 2007

When BMPs can’t meet stormwater permit rules

Clear Water Compliance Services

Chemical flocculation draws soil particles together to create larger, heavier particles that can be removed through gravity settling or filtration.

|

The construction permit requires an on-site certified erosion and sediment control lead to monitor, evaluate and report on best management practice (BMP) performance for projects with more than one acre of disturbed surface. Larger sites require discharge water sampling during storm events.

The new permits have also established water quality benchmarks for turbidity, pH, and industry-specific pollutants.

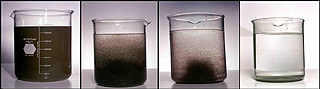

In these runoff samples taken from a construction site, only the jar on the left met requirements. |

In many cases, conventional BMPs are incapable of reducing turbidity and other pollutants to acceptable levels. Traditional installation of straw wattles, silt fences and similar measures are insufficient for removing suspended particles to levels suitable for the new requirements. This reality has greatly increased the need for advanced stormwater treatment techniques.

Advanced techniques

Advanced stormwater treatment for construction sites typically requires chemical enhancement of the stormwater. Extremely fine particles, typically silts and clays, can stay in suspension for decades without settling due to their relative size and ionic charge. The chemical, or flocculant, acts on an ionic level to draw soil particles together and create a larger, heavier particle called a floc. The floc can then be removed through gravity settling or filtration.

The Port of Seattle is using a chitosan-enhanced sand filtration system on its Third Runway project. More than 100 million gallons of stormwater have been treated since November 2005. Images courtesy of Clear Water Compliance Services

|

Gravity settling is typically used in batch treatment processes where the discharge rate is not a limiting factor. Filtration is commonly used to reduce processing time or provide continuous, high-rate discharge.

There are primarily three advanced treatment methods in the market today, and all have different capabilities and limitations to consider prior to implementation. These methods include cartridge filtration, electro-coagulation and chitosan-enhanced sand filtration.

Cartridge filtration typically employs media containing a wound fiber filter. Treated water flows into the housing and through the media to remove flocculated sediment particles. Various media are available for use in cartridge filtration to remove a range of pollutants. The technology can be effective in low-flow situations or as a “polishing” component for batch treatment. Replacement media and maintenance costs for these systems can be high and high-flow rates can impede performance.

The electro-coagulation (EC) process uses charged iron plates to flocculate sediment particles. The electrically charged iron plates release iron atoms into the turbid water. The iron atoms act as a flocculant on the suspended sediment particles. Treated water is then forced through sand filters to remove the floc particles. EC has demonstrated the ability remove hydrocarbons, metals and other pollutants along with the fine particles in stormwater.

Ecology recently granted a general use designation level for chitosan enhanced sand filtration (CESF) to reduce turbidity and associated pollutants on construction sites. Chitosan is made from chitin, which is derived from recycled crustacean shells. Chitin is transformed into chitosan to create a biodegradable flocculant.

CESF is a versatile and effective treatment option for reducing extremely high turbidities to below benchmark standards at high flow rates. Simply put, this technology can quickly remove suspended particles from stormwater to manage rain events that cause significant water quality issues.

Ecology requires trained and certified technicians operate CESF systems due to the potential for rapidly changing water quality conditions, the use of high-pressure filtration vessels and the complexity of the water chemistry used in the treatment process.

Choosing the right technology

The three advanced treatment methods benefit the construction industry by extending the construction season through the rainy season while maintaining site compliance with the NPDES permit requirements. This allows projects to stay on schedule and minimize the potential for water quality-related stop-work orders, fines and lost profits.

|

A chitosan-enhanced sand filtration system is being used to treat runoff from construction work at the Beacon Hill Reservoir.

|

The question then becomes, how does one choose the right technology and what can be expected from a service provider?

The first thing to consider is the size of the site. The total disturbed area, combined with the anticipated rainfall for the two-, 10- and 100-year rain events, will dictate the system design criteria and required discharge flow rate. Keep in mind, the design storm events are only statistical models. Both the 10- and 100-year storm events have occurred locally in the past two consecutive years.

The system design criteria will include calculations for required storage prior to treatment, allowable discharge rates to surface waters and the required treatment system footprint. In most cases, increasing the size of storage ponds will reduce the cost of water treatment.

Stormwater management and treatment providers range from equipment rental companies to comprehensive stormwater management services (treatment system design, permitting, installation, operation and reporting). There are a number of critical factors in selecting a stormwater treatment system. It is important to enlist the assistance of a knowledgeable service provider who can evaluate the physical, chemical and regulatory limitations of a project.

Costs of advanced treatment depend on unpredictable factors such as total rainfall, storm intensity and the effectiveness of site BMPs. It is important the service provider clearly defines any assumptions and demonstrates that all the factors described above have been considered in the recommended design. As stated before, most of these advanced technologies require an Ecology-certified technician to operate the equipment.

Getting on board early

Heavy rain can blow out conventional stormwater treatment measures.

|

One final consideration in applying advanced treatment is early implementation. Design limitations can be more easily addressed during the planning stages of a project than during construction. All of the systems described in this article also use similar equipment. Storage tanks and filters are in high demand during the rainy season. The 2006-07 wet season set rainfall records in Washington state. During the same time period, there were no storage tanks available for rent or purchase west of the Mississippi River.

If a project is anticipated to remain active during the rainy season, a stormwater management service provider should be on board early to ensure equipment availability.

| More information |

|

To find out more about advanced treatment technologies to control stormwater runoff, visit http://www.ecy.wa.gov/programs/wq/stormwater/newtech/index.html.

|

Meeting the water quality standards established in the NPDES permit can be challenging, especially during the rainy season. The very fine particles suspended in runoff are simply too small to settle or be removed by conventional BMPs. Advanced stormwater treatment on construction sites is gaining popularity with regulators and contractors by allowing construction to continue during the rainy season while maintaining compliance.

Nathan Hardebeck has been in the stormwater industry for eight years. He has been involved with industrial stormwater compliance issues, post construction BMPs, and is now working in the construction stormwater and groundwater treatment arena.

Other Stories:

- Cleaning up stormwater runoff on freeways

- New Seattle hotel to marry luxury with green

- Lakehaven solves water woes with ASR

- Treating rural wastewater is a daunting task

- The Emerald City’s tourist industry turns green

- Are nanomaterials another environmental worry?

- Tribe’s waste plant doesn’t raise a big stink

- Contaminated site? Let Mother Nature help

- Why integrated design is off to a slow start

- Study your options when banking or reserving wetlands

- Developers must dodge newly discovered fault hazards

- A solution to our dwindling water supply lies below

- What to know when buying a contaminated site

- Blending a new community into the environment

Copyright ©2009 Seattle Daily Journal and DJC.COM.

Comments? Questions? Contact us.