|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

June 1, 2000

Creating a little desert indoors

Journal Staff Reporter

Rain is natural order on construction jobs in the Northwest. Contractors figure in wet weather when drafting construction schedules, and many say mitigating dampness can be key in controlling costs -- although it's not always possible.

But one business' bane can be another's financial gain. Here in the nation's rainy region, new services and technologies are thriving that help keep jobs on track in poor weather. From the Tacoma-based L. Darling Corp.'s "Rite in the Rain" waterproof paper, to indoor modular construction, folks are figuring out how to beat the rain.

Likewise, Munters Corp. -- an international firm specializing in humidity control -- says it has a solution for controlling the climate inside buildings under construction.

|

The company recently began using large desiccant dehumidifiers to provide better working conditions on large job sites. Desiccant dehumidifiers are most commonly used in drying flooded buildings, while direct-fired heaters -- which use propane -- handle construction drying.

But according to Don Schnell at Munters' Kent office, desiccant dehumidifiers do the job better.

That's because instead of solely heating up the air, as with direct-fired heaters, dehumidifiers actually lower the vapor pressure, creating a desert-like atmosphere between 65 and 75 degrees Fahrenheit.

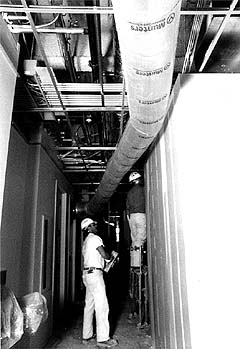

Here's how it works: Munters technicians suspend plastic tubing -- which is connected to dehumidification machines place outside the building -- from the ceiling of the structure. The dehumidifiers remove moisture from the outside air, then duct the dry air inside the building via the tubing. The air inside the structure is then pressurized, and moisture is removed.

Chris Cortinas, industrial account manager for Munters' Washington state division, explained that as moisture is re-introduced inside the building -- for instance, as drywallers place mud on the walls -- the dehumidifier system continues to pick up that moisture, maintaining a dry atmosphere 24 hours a day.

Cortinas said it takes about three hours for the system to completely dry out the air inside a work site. And, according to Schnell, the equipment can remove up to 300 gallons of moisture in the air per day, depending on the building.

The upshot: work can move at a quicker pace and crews can begin projects earlier in the spring -- a huge boon in the Northwest where construction seasons are notoriously short, Schnell said.

Contractors who have used Munters' dehumidifiers say the results were impressive.

S.D. Deacon, a general contractor with offices in Seattle and Portland, used desiccant dehumidifiers on a project to build a 51,000-square-foot commercial building in Portland.

Joe Schueller, superintendent at S.D. Deacon, said his crews were able to put up drywall in the morning, then begin sanding after lunch. "Watching this was amazing, I couldn't believe it."

Schueller figured at least a couple of weeks were shaved off the construction time thanks to the dehumidifiers. S.D. Deacon opted for the technology to ensure floor coverings could be laid down efficiently, but the dehumidifiers had some side benefits as well: interior painting was started earlier than scheduled, and the dry walling process moved much more quickly.

At Union Station in downtown Seattle, Opus Northwest is using Munters' dehumidifiers to dry sheet rock mud for a tenant improvement project. Project manager Dexter Brown said the technology was more expensive upfront, but about half the cost in the long-run.

"The dehumidifiers have saved me a lot of money, and reduced our drying cycle to about 11 to 12 hours," Brown said. "For our situation at Union Station, the dehumidifiers worked well, and we are very pleased."

Generally, portable propane heaters are used to dry sheet rock. But, as a product of combustion, the heaters actually throw moisture into the air, Brown noted. Thus, achieving the same success as a dehumidifier takes much more effort, and money.

|

"We would have had to use a huge amount of propane, plus more labor because the heaters -- which burn unevenly, at best -- must be monitored 24 hours a day for refueling and fire safety," Brown said.

Dehumidifiers can also work well in partially open buildings. At Union Station, one wall was missing, and covered with a temporary plywood structure. Nevertheless, the dehumidifiers still expelled moisture.

Brown did observe some drawbacks. Because the plastic tubing is suspended from the ceiling, some wetness remained around the edges of the walls along the floor. The problem was solved after Munters installed more tubing along the lower perimeter of the building.

"Overall it worked well, and any complications were addressed right away by Munters-- their service has really been great," Brown added.

So why hasn't the technology caught on?

Schnell said it is gaining popularity in the Northwest, where news of moisture-combatting products tends to spread rapidly. However, there is still some ignorance about the costs and benefits of the dehumidifiers, he said. Some contractors stick with the more conventional direct-fired heating without investigating the alternatives.

Mark Fowler of Northwest Wall and Ceiling Contractors Association agreed.

"Old habits die hard in the construction industry," he said. "Contractors get used to doing things a certain way and don't want to change, despite the benefits."

As an architectural consultant for NWCCA, part of Fowler's job is writing specifications and standards for the ceiling and wall industry. He has toured several job sites where Munters' system was in action, and -- like the contractors he spoke with -- was impressed.

"Joint compounds have to dry evenly. When you walk into a building with the dehumidifiers, you can feel the dry air throughout the building," he said. "That translates to a significant reduction in job site problems."

Fowler noted joint failures are common during the rainy season due to improper drying. He said dehumidifiers can resolve the moisture issue and architects should insert the system in their project specifications.

"I think this (dehumidifiers) is going to be one technology that really takes off," Fowler said. "It will be big, very big on prominent projects."

Previous columns:

- Living in a cardboard house, 02-24-2000

- $17 million emergency center spurred by fire training tower, 01-13-2000

- Landscape problem? Cover it with a 'rock', 01-06-2000

- Life on the leading edge of sustainability, 12-23-1999

- Commuter Building now a traffic-stopper, 11-18-1999

- Permeable pavement can reduce storm runoff, 11-04-1999

- Job order contracting may come to local agencies, 10-28-1999

- Industry out to rebuild reputation of EIFS, 10-21-1999