|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Architecture & Engineering

| |

|

March 30, 2023

New form of team work needed for multifamily projects

Johnston Architects

McKay

|

While building information modeling software is changing the way building design is communicated and documented, the design and construction process itself has not fundamentally shifted to meet the promise of the technology as applied to private multifamily development. A different approach to design teamwork is necessary to move the industry forward.

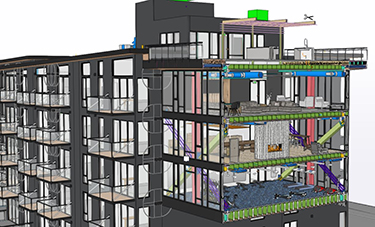

Johnston Architects was approached by MBG Co. to lead the design for its 187-unit Bay Bowl apartments in Bremerton. The project itself is complex, located on the waterfront and consisting of two distinct buildings linked by an elevated bridge connector. The owner brought a strong mandate to collaboratively develop a singular, highly detailed design model with a team-based methodology. This alternative approach, in line with a process honed from large public projects and applied more practically to market-rate multifamily development, is dubbed 22nd Century Design and Construction (22 CDC). It made possible the complete design for Bay Bowl and is resulting in tangible time and cost savings.

The traditional architectural process documents design intent and is not a “complete” design — that is, not detailed to fabrication level. In this old model, the consultant team works together, but sequentially, beginning with the architect and working through the engineering chain. Several co-linear design models are developed by each specialist. The resulting design intent is documented in 2D drawings conveyed to a separate construction team to be brought to physical life. The contractor applies a heavy contingency to cover the unknowns and the subcontractors produce their own fabrication-level drawings and models.

As each distinct discipline works on their “portion” of the project, they may identify new issues that require cycling back through the team and revisiting the design repeatedly. Coordination issues emerge during the construction process, threatening to erode the design concept and owner’s budget. It is a time-worn process plagued by incomplete communication, difficult coordination, time and material inefficiency, and loss of information in each step of translation. Such inefficiencies add up to a significant cost of time, money, uncertainty, and environmental impact.

The 22 CDC design process deployed for Bay Bowl solves for the myriad issues of a traditional design methodology. A singular design team was assembled with a commitment to open communication and the creation of one collective, highly detailed BIM design model. From the early design phase, the entire team met frequently (at least weekly) to make decisions, provide continual feedback, and closely coordinate on fundamental elements such as whether the framing system would be wood or metal. The signature design element of Bay Bowl — the central amenity bridge spanning between the two buildings — was shaped by the collective team weighing the merits of several structural options to arrive at the right customized solution. Initially, a seismic joint was expected at the bridge condition, but the structural team (GPLA Inc.) worked magic to engineer a rigid frame that simplified the mechanical and fire services and architectural expression all at once. To reduce earthwork costs, the geotechnical engineer kept abreast of changes to the footprint and utility design, and weighed in on ways to eliminate shoring on the project.

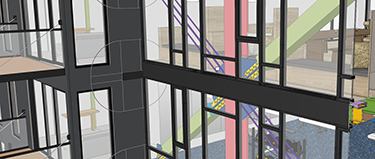

The 22 CDC process is decisive since the whole team makes decisions together and considers them from all angles from the start. There are no second-guesses, late opinions, or backtracking. Every member of the team models in BIM — and critically, structural and MEPF teams model to a Level of Design (LOD) 400 fabrication level. The individual models are (concurrently) aggregated into one singular model that exists in the cloud in real-time. The team works simultaneously, not sequentially, to develop the aggregate model and coordination issues are discovered and solved during design when changes cost much less. The resulting single model is as close to an as-built as possible, even before the start of construction, and carries the project through construction and into facility management beyond.

When the single design model is developed to such a high level of accuracy, complete material take-offs can be harvested before construction begins. Competitive bids can be leveled and contingencies greatly reduced. Delegated design scopes can be completed much earlier. The material acquisition sequence is freed to respond to market conditions and exact quantities can be purchased to minimize waste — a fundamentally simple way to reduce environmental impact and cost in one stroke. Furthermore, construction work can proceed simultaneously rather than in sequence to save time because accurate prefabrication becomes possible. Enhanced coordination leads to issue resolution during design and a “complete” design is provided to the construction team, resulting in a significant reduction in change orders and work stoppages.

At Bay Bowl, the construction schedule may realize a 30% time savings and 20% cost savings, leading to very real fiscal and risk-reduction benefits for the developer.

Applying the enhanced accuracy and coordination of complex public project delivery methods to private, market-rate multifamily and mixed-use projects is transforming the way Johnston Architects designs housing projects. The 22 CDC design process is faster, more accurate, and more predictable through its early and continuous team communication and collaborative single aggregated BIM-based design model. But the methodology holds more promise than the process itself. It allows the design team to work as one, protecting truly special elements of the design concept from erosion via engineering realities, like supplying building MEPF services around structural obstacles.

At Bay Bowl, the design team is collectively ensuring the floor-to-ceiling glass in the amenity areas, lobby, and apartment units is clear of obstructions, maintained pure by clashes detected early, trades coordinated, and details worked out before a single nail is driven. Accurately executing on a design vision from concept to complete physical building requires a rigorous, complete, predictive and team-based process that is nothing short of revolutionary.

Megan McKay joined Johnston Architects in 2006 and was promoted to partner at the women-owned firm in 2017. She has been instrumental in the design and project leadership of award-winning mixed-use developments with an emphasis on multifamily projects that encourage community engagement and enhance urban environments.

Other Stories:

- In Edmonds, a park runs through it

- Engineering gets specialized in response to increasing complexity

- Equitable development: nice to have or essential best practice?

- At Glover Middle School, the lighting runs through it

- Engineering solutions, as waters rise

- Revitalizing downtowns with office-to-residential conversion

- Structures and sustainability: pursuing net-zero carbon emissions

- Employee ownership for all: an alternative to the ESOP

- So you want to be a rock star (marketer)

- Natural direction is a new path in architecture