|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

July 27, 2023

How computational fluid dynamics ensures optimal heating and cooling at Colman Dock

FSi Engineers

Reeve

|

Sustainability, innovation, and resilience are hallmarks of the values held by Washington State Ferries (WSF). The Colman Dock renovation modernizes the multimodal terminal, greatly improves its seismic resilience, makes great strides toward energy efficiency, and prepares the complex for future code requirements.

“WSF has admirable goals for Colman Dock,” said Ola Jarvegren, principal at FSi Engineers. “They came to this project with really big ideas. It's exciting to work with agencies who take sustainability on as a primary goal. That's why it has been absorbing from our first work in 2013 to the phase we're in right now.”

From the very beginning, the project presented unusual technical challenges. WSF needed the terminal to remain functional during the entire construction period, which required carefully planned project phasing to keep both foot and auto passenger traffic flowing smoothly. The power source for the project also changed while the design was well underway, requiring the design team to pivot its approach. The location in an active seismic zone required exceptional levels of structural engineering.

ROOTED IN PAINT HANGARS

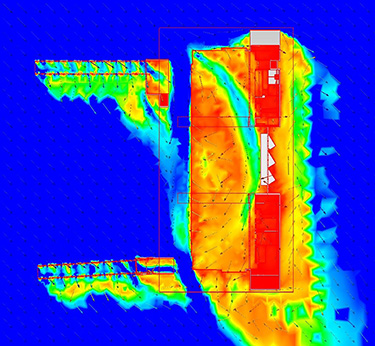

With 10 million passengers annually and 70% of WSF's total foot traffic, human comfort is another primary concern for the terminal. FSi used computational fluid dynamics (CFD) airflow modeling to ensure optimal heating and cooling. CFD provides information about the speed and temperature at which air flows through a given area. The modeler creates a variety of scenarios with variables such as the placement of doors and windows, building orientation, location of ventilation, and other factors.

FSi built its CFD expertise at an iconic Northwest aviation company designing paint hangars to optimize airflow, ensuring even coverage of the aircraft and to minimize waste and overspray. Through dozens of projects, performed over decades, FSi gained the skills to extrapolate the use of CFD to other applications.

For the Colman Dock project, FSi used CFD and data on prevailing winds to determine the structure could use natural ventilation for passive cooling. The facility's operable windows take advantage of the cool breezes coming off the water, supplemented with high-volume, low-speed (HVLS) fans. This eliminates the need for mechanical cooling, saving energy and contributing to WSF's sustainability goals while maintaining passenger comfort.

CFD verified that in-floor radiant heat would perform well in the winter. The models demonstrated radiant heat would outperform traditional HVAC by warming the people and fixtures rather than the air. Radiant heat is more effective at keeping the temperature comfortable, particularly in areas where doors open frequently as passengers enter and exit the facility. The HVLS fans play a part here as well, by moving warm air from the high ceilings back down to passenger levels.

LEADING-EDGE INNOVATION

FSi started working on Colman Dock a decade ago. Since then, Washington state and the city of Seattle have both implemented ambitious building and energy codes in their commitment to sustainability in building design. The AEC industry has embraced these code changes and continues to innovate, incorporating new technologies and using existing equipment in creative ways.

One example of innovative equipment use involved dedicated outdoor air system (DOAS) units. WSF does not allow air conditioning in its passenger facilities, making DOAS the ideal mechanical solution to decouple necessary ventilation from mechanical heating and cooling.

“It's interesting to see how fast the leading edge of sustainability changes,” mused Jarvegren. “When we started this project, DOAS was innovative and unusual. Now, we see them on most of our projects. I think that comes from agencies like WSF that look ahead and set an example of building in new ways. They bring ideas to life by using them in public projects. Then other sectors follow along. That drives the equipment manufacturers to keep up with the trends, and soon it becomes the design standard. It's a great upward spiral.”

RESILIENCE UNDERNEATH IT ALL

Resilience is a key aspect of sustainability. WSP, which led the engineering team, provided vital features through its structural engineering. The dock is in a seismically sensitive area and requires deep pilings for support, and flexibility to withstand the wave action of earthquakes.

“The pilings have to be deep enough to penetrate two layers of liquifiable soil to find a solid foundation in the glacial soil. This means that the Colman structure is approximately 10 stories tall, but most of it is below the surface,” said Mike Wray, WSP senior vice president and project manager. “This is necessary to meet WSF's goals of protecting occupants' life safety and allowing safe egress post-earthquake.”

WSP designed 5 acres of new concrete trestle, supported by driven pipe piles and drilled shafts. The design is informed by the company's advanced soil-structure interaction analysis, which uses numerical modeling rather than empirical approaches. The findings were peer reviewed.

WSF TARGETS LEED SILVER

FSi is leading the LEED process, preparing the reports and coordinating with each discipline. Together, the ad hoc team is working to earn the maximum points possible to attain WSF's goal of LEED Silver, under version 4.1 NC.

“The design team collaborated to incorporate sustainable design features across disciplines and significantly reduced energy and water consumption,” said Matthew Veloz, FSi energy analyst and LEED consultant. “Washington state is making a strong push toward decarbonization, and the hydronic system is well-suited for future electrification. Meanwhile, the savings gained from this phase make excellent use of their energy budget.”

The team gave WSF the sustainable, measurable results it wanted. The design achieved energy savings of 35% over the LEED baseline, a particular challenge in a non-standard facility like the main terminal. Projections also estimate a reduction in water use of 40% above the LEED baseline. Both energy and water are metered, giving WSF data to maintain these savings over time. The team also earned LEED points for indoor air quality, focused on filtration and CO2 monitoring. The project is on track to meet its LEED Silver goal.

150 YEARS AND BEYOND

First constructed in 1882, the Colman Dock, in its many forms, has served the people of Washington state for nearly a century and a half. It has a rich history as a part of Seattle's working waterfront, serving a variety of commercial purposes. It burned in the Great Seattle Fire in 1889, was rebuilt, then extended in 1908. Successive rebuilds and improvements have kept it a vital part of both city and state economies. With the completion of this project, Colman Dock has the capacity and resilience to continue its legacy well into the future.

Ro Fonder Reeve is in marketing communications and social media at FSi Engineers in Seattle, and is also a freelance writer.

Other Stories:

- New flagship ferry terminal restores salmon habitat, honors tribal history

- Transformed dock is a symbol of progress, sustainability, community

- 6-year rehab faced many challenges

- Elemental geometries steer design of Seattle’s new ferry terminal