|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

October 12, 2000

New research can help building owners who are shaken up by quake hazards

EQE International

The Seattle community has become increasingly aware that the Puget Sound is earthquake country. The challenge facing us is not how to retrofit existing facilities to improve life safety, but rather how to minimize its impact on operations and maximize the value received for this investment.

|

|

Courtesy of Taylor Devices, Inc./Graphics by Keith Varney

|

Today, structural engineers use new approaches to achieve improved earthquake performance and reduce upgrade construction costs.

Traditional seismic upgrade solutions typically involve strengthening connections and adding walls or braces. Recent research has yielded innovative techniques to resist the forces of nature by absorbing or dissipating destructive energy before it is transmitted to the building frame.

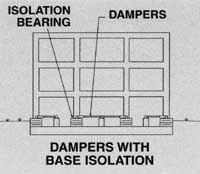

Seismic base isolation involves installing special bearings between the structure and foundations to isolate the superstructure from violent ground shaking. The isolators can be made from laminated elastomeric (rubber) compounds, or specially coated steel castings.

These bearings transmit only a fraction of the earthquake energy so that, in effect, the building sees a smaller earthquake. Advantages of base isolation include high damping (building oscillations are quickly dissipated), relatively few construction areas (typically at ground level only), and an expectation that the retrofitted building would experience minimal damage, allowing for immediate resumption of operations.

Base isolation is a proven technology that in many cases is not prohibitively expensive. It is an excellent solution for seismically vulnerable structures with essential operations and limited available construction areas.

Courtesy of Scougal Rubber

|

Base isolation was employed for the seismic upgrade of the Washington State Emergency Operations Center at Camp Murray. Base isolation may also be used for the Aurora Bridge retrofit (eliminating expensive foundation upgrades), and is part of the restraint system for the new football and soccer stadium currently under construction in Seattle.

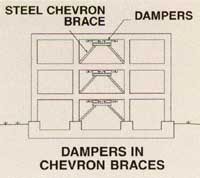

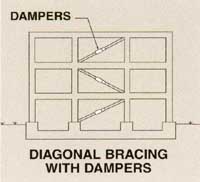

Another method of improving a building’s earthquake performance is through the use of dampers at key locations, typically within braced frames.

Structural dampers act like shock absorbers in a car. Dampers include hydraulic cylinders (like shock absorbers), friction devices (like brake pads), specially designed steel plates (like the leaf springs), and specially designed wall panels, filled with viscous fluids.

The advantages of damper systems include: lessening of ground motions and forces within the existing structure, limited foundation work (construction cost savings), low maintenance and predictable structural damage.

| Making your seismic upgrade a success |

Various options are available to the design team in finding an appropriate seismic rehabilitation solution. Techniques are available today not only to protect lives, but also maintain operations and investments at a reasonable cost. Each project is unique; however, the basic steps for finding the optimal seismic upgrade solution are:

Creativity, communication, and an adequate design budget will result in a solution that anticipates construction issues and meets the owner’s seismic performance expectations. It is well known that Seattle is at risk of a major earthquake. The Federal Emergency Management Agency ranked Washington state second only to California in terms of potential overall economic loss in the event of a major regional earthquake. Yes, many of our structures are vulnerable to significant damage, but many facility holders are proactively minimizing their risk. There is too much at stake to do otherwise, as demonstrated in recent devastating earthquakes in Taiwan and Turkey. The robust regional economy and future growth can be preserved. Structural engineers have the tools to help. Techniques are available today to keep retrofit costs reasonable even at extremely hazardous sites such as near-fault locations (Seattle fault) and weak soil sites (along the Duwamish waterway and in Kent-Auburn Valley). |

Viscous fluid dampers have been used by the aerospace industry for many years to resist shock and blast loading. This system is used to resist wind and earthquake forces on the retractable roof at Safeco Field. Damper devices are likely to be used in the seismic upgrades for the King County Courthouse and Bellevue City Hall. Friction dampers were used in the seismic upgrade of an elevated water reservoir in Kent and at the Boeing facility in Everett.

Buckling-restrained steel-braced frames (BRBF) is another attractive solution similar to conventional steel-braced frames (where diagonal in-wall members resist lateral loads), but with better energy dissipation characteristics.

In a BRBF system, bracing members consist of a steel rod core surrounded by concrete-filled steel pipe. The inner rod acts as a tension member with the surrounding concrete-filled tube resisting compression buckling under cyclic seismic loading. This solution is applicable for replacement of existing steel-braced frames or for new construction. BRBFs are nearly as economical as steel braces, but perform much better.

Other retrofit options

Seismic upgrades need not result in the loss of windows or extensive demolition of architectural finishes. Creative options at the disposal of structural engineers include:

High-strength shear panels for wood-framed structures. Relatively narrow engineered frames are available for projects with limited wall areas, for installation between existing windows, or adjacent to garage door openings.

Fiber-reinforced wrapping technology was developed as an alternative to steel jackets for seismic strengthening of highway bridge columns. Fiber wrap applications in buildings include sheathing of nonstructural walls (clay tile) and roof diaphragm and column reinforcement.

The Center Core method was developed in California for the retrofit of historic unreinforced masonry buildings. The method is particularly useful when it is desirable to preserve both the inside and outside architectural fabric of a building.

The installation process is: core a vertical hole from the top of the wall into the footing; place a steel reinforcing bar into the hole; and grout the hole solid.

Center core reinforcing improves the ability of a wall to resist in-plane and out-of-plane loads in a ductile manner. The core permits an unreinforced masonry wall to behave like a reinforced masonry wall.

Construction cost savings can be significant. For example, the estimated cost to retrofit a 1928-vintage historic stone masonry meetinghouse in Salt Lake City using a conventional shotcrete approach was $1.7 million. The estimated cost for a center core upgrade was half that due to fewer disturbed finishes.

Buttressing involves external seismic bracing or walls. This solution can be used when expanding existing vulnerable structures. Buttressing may be used in the proposed Harborview Medical Center expansion and upgrade project.

Mark R. Pierepiekarz, P.E., S.E., is a senior project manager and associate with EQE International Inc. in Seattle. EQE specializes in structural design and innovative seismic retrofit. Recent retrofit projects include Bellevue City Hall (dampers), historic meetinghouse in Salt Lake City (center core), and The Aerospace Corp. headquarters in Los Angeles (base isolation).

Other Stories:

- Not imitating can be sincere flattery, too

- Renovations bring boom times back to Pioneer Square

- Building moves to head of its class