|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

August 3, 2000

A frothy solution to fend off earthquakes

By JON SILVER

Journal Staff Reporter

The costly and labor-intensive work of seismic upgrading for walls in older buildings may become a thing of the past.

|

The Masonry Composite Earthquake Rehabilitation System uses an expandable urethane foam that is used to strengthen support for buildings by filling in and bonding to all the interior spaces between the walls.

The elementary school, like many buildings built between the early- to mid-1900s, was constructed using hollow clay tile walls that left cavities for running mechanical piping and ducting as were convenient for building lockers and cabinets. Ron Vandehey, Miller's principal, said that while clay tile was used because it was considered fire resistant and economical, it's liable to collapse during earthquakes.

The usual method to upgrade such buildings has its drawbacks, though.

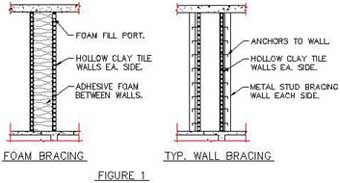

Normally, clay tile walls are braced by strong-backing both sides with new metal stud walls that are supported at the floor and roof. The stud walls are then secured to the clay walls with a metal screw called a Helifix.

But the added walls, which are up to 6 inches thick, can be intrusive. In the case of the elementary school, not only would adding the stud walls eat up corridor and classroom space, it would generate the associated costs of removing or replacing items such as chalkboards, lockers, shelving, artwork and cabling.

The Portland Public School District encouraged Vandehey's firm to seek out a better option. "We looked for an inexpensive solution," said Vandehey. "It was either find a better way to do it or we don't do it at all."

While the method his firm devised doesn't compare to a walk in the park, it is a bit like spraying a garden hose. From even a very small access hole, flowable urethane foam can be piped in fill an entire wall cavity. Once the foam expands to fill the cavity, it bonds to all of the interior surfaces of the wall and hardens. When the process is completed, the foam can support the clay tile walls in the event of an earthquake.

The cost of applying the urethane is similar to that of installing the stud walls, but Vandehey estimates that the school district pocketed $190,000 as a result of the saved time, labor and finishing costs. The foam system would also benefit those who don't want to lose wall coverings such as mosaics or murals, which, said Vandehey, "would take the character out of their structures."

|

In addition to completing seismic upgrading projects, which includes the Oregon Capitol, Miller Consulting Engineers has worked with urethane for commercial refrigeration panels since the late '70s. To build the panels, the foam is injected between two steel skins, which forms a composite structure that makes a strong, effective insulator. The foam's insulation properties also helps muffle noise.

Tests of the new application were subject to problems at first. "We couldn't get low enough expansion for the foam," said Vandehey. "It expands quite a bit.

"There was also a concern that if the clay tile was dirty, the urethane might not adhere well," he added. "But when we tried to pull the tiles apart, they were stuck like superglue."

The foam, he says, will work with "any kind of masonry with a cavity" such as brick or concrete block, though not where walls are either too high (30 feet) or too narrow to contain enough cavity space.

Though the elementary school is the only site that has been upgraded with the foam system so far, Vandehey sees a big future ahead for it. "It'll become a standard of the industry," he predicts.

Dull Olson Weekes, the architectural firm for the elementary school project, did not return a phone call seeking comment.

Previous columns:

- Paint additive really beats the heat, 07-27-2000

- A revolution in home building?, 07-20-2000

- How to keep 'kool' when it's hot, 07-13-2000

- AGC members are 'best supporting actors' for new Tacoma arts center, 07-06-2000

- Heating a home on two bits a day, 06-29-2000

- WSU offers design-build management degree, 06-22-2000

- Siding panels use gravity to keep the rain out, 06-15-2000

- Company has the poop for keeping birds away, 06-08-2000