|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

July 31, 2003

Building with your head in the trees

Journal Staff Reporter

Photos courtesy of TreeHouse Workshop

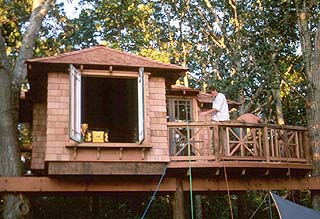

TreeHouse Workshop carpenter Shane Wyatt perches atop a structure in Northern Oregon that is built around a seven-stemmed oak tree.

|

Treehouses aren't just for kids. In fact, with a local company specializing in treehouses that are like a home away from home in your backyard, you might find yourself locking the kids out.

Seattle-based TreeHouse Workshop has built many treehouses locally and has even shipped a prefab unit as far away as Massachusetts.

Jake Jacob and Peter Nelson are at the heart of the company. The pair formed the company in 1997 from an idea to fuse their talents -- Jacob the technical expert and Nelson the master builder.

To date the pair have built about 40 structures, mostly from recycled and reclaimed materials, sometimes adding electricity. Costs range form $30,000 to $200,000.

Jacob culls materials from demolished buildings and homes and scavenges the Columbia River for abandoned boom logs. "We use a lot of reclaimed wood," he says. "When the treehouse is finished, it looks like they have been there forever."

Nelson has authored several books on the trade. His first book, published in 1994, is called "Treehouses: The Art and Craft of Living Out on a Limb."

The company operates with four employees. Many former employees act as specialty contractors for the treehouse projects.

The TreeHouse Workshop's customers use their creations as offices, guest bedrooms, art studios or just a place to hang out and relax. Most are built for adults, but sometimes the kids find a way of taking over.

Jacob says there are a variety of reasons people want to build treehouses but the main reason is that it "appeals to something they remember from childhood."

This treehouse was built in Seattle and assembled in Cape Cod using recycled beams, wood and windows. |

To get an idea of what this duo can build in the trees, one project covers 315 square feet on top of a six-tree stand of Douglas firs, has a living room, bedroom and bathroom with an incinerating toilet, and features 15-foot-high cathedral ceilings. Another measures 23 feet from top to bottom, weighs 18,000 pounds and stands on seven supporting knee brackets. The structure doesn't even touch the tree's trunk, which allows for the tree to grow, sway in the wind and keep insect traffic on the move up and down the trunk.

Over the years, Nelson and Jacob have consulted with fellow builders, arborists and engineers to develop ways of attaching to and building around trees to minimize damage and add longevity to the structure. The team also consults with and uses other professionals such as specialty bridge and trail builders, wood carvers, wildlife biologists, naturalist habitat constructors and landscape architects.

"A treehouse starts with a site visit. Ultimately the client is the designer and we try to facilitate their vision into the realm of our craft," said Jacob. "In the end, treehouses are very much dictated by what the trees dictate to us."

The trees are investigated and measured. Photographs are taken. The information from the site is taken back to the shop and sketches are made for the client. When the design is established, a platform is built.

After the platform is in place, a template is made and the tree is studied and the locations of limbs are measured. Back in the shop, a mock-up of the platform is made and the treehouse takes shape. Wall and roof panels are built in the shop and then disassembled for shipment to the site. Whatever interior work is needed is finished at the site.

The company custom fits the brackets for each tree. One of Jacob's rules is "perch don't pin." Artificial limbs are installed so that the structure can "float" in the tree.

The way the treehouse is attached to the tree is calculated to avoid tree damage and the possibility of rot. Cables, ropes and supports between a fork in the tree can be fatal to the tree and are never used. Rather than nails that can contribute to rot, bolts are used for attachments and are fitted in a vertical pattern with 12-18 inches between. The pattern and distance disrupts only one channel of the tree's nutrient flow and avoids rot developing between bolts.

"GL" or Garnier Limb anchor bolts designed by Michael Garnier, a treehouse builder in Oregon, are used as artificial limbs to hold up to 8,000 pounds.

|

One big bolt is better than several smaller ones. The tree will heal the wound and seal it so it becomes part of the tree. Eventually, the tree will accept the load and grow accordingly.

Angular blocks or brackets provide flat vertical or horizontal surfaces for beams. The treehouse rests on the support system and does not touch the tree directly. This prevents friction burns as the tree sways.

Jacob said he finds inspiration and techniques from other builders. Each year there is a World Treehouse Conference in Oregon, where about 60 builders come together to trade stories.

The company also sponsors its own hands-on workshop in October where a structure is built for a client in about six days. Last year, 17 people participated.

The TreeHouse Workshop usually steers people away from building structures that will be used as homes, since the cost of the structure's support raises the price significantly. To fit a tree-based structure with plumbing is complex, requiring considerable support and design considerations. Permits are usually required for structures with plumbing and the structural safety of the house may require an engineer's report. Electricity tends to be less of a problem if a "temporary" extension lead is used as a supply.

Nevertheless, the company is working on a fully-equipped and permitted treehouse in San Diego that will be plumbed and powered. It will cover 955 square feet inside with 650 square feet of decking in seven California oak trees. It will use supplemental support from artificial trees crafted from steel and concrete and molded to look like real wood.

Workshop information is available on the company's Web site at www.treehouseworkshop.com. The phone number is (206) 782-0208.

Previous columns:

- Builders' group creates a university, 07-17-2003

- Construction association starts new safety program, 07-10-2003

- Charter headquarters is new and green, 07-03-2003

- Low-rises studied for quake, wind effects, 06-26-2003

- Put a little fiber in your sewer's diet, 06-19-2003

- Local contractor builds in Puerto Rico, 06-12-2003

- Digging? Try sucking the dirt instead, 06-05-2003

- In pursuit of the perfect glu-lam, 05-29-2003