|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

October 28, 2021

Transforming Seattle’s historic KeyArena

Thornton Tomasetti

Farber

|

Morgen

|

The Seattle Center Coliseum has a long history of hosting major sports and cultural events. Originally constructed for the 1962 Seattle World’s Fair, the venue served as home to the Seattle SuperSonics basketball team for more than 40 years and played host to everything from one of the Beatles’ final stage performances to the NBA All-Star Game.

Renovated and rebranded in 1995 as KeyArena, it has seen its ups and downs over the years, including the loss of the Sonics franchise. But the arena’s latest transformation is truly one for the books. After an extensive renovation and expansion, Climate Pledge Arena is a state-of-the-art venue worthy of the city’s newest sports team, the Seattle Kraken. The new 800,000-square-foot, below-grade arena holds more than 17,000 fans for hockey, basketball, concerts, and other events, along with a new below-grade parking garage and tunnel to access the loading dock.

As concertgoers and Seattle Kraken hockey fans filled the arena for the first time last week, they likely appreciated its new look, amenities, and high-tech features without giving much thought to the work that went into it. Oak View Group’s renovation of the arena presented several complex challenges for the architect Populous and structural and construction engineer Thornton Tomasetti.

| Project Team |

|

Owner: Oak View Group Owner’s representative: CAA Icon Architect: Populous Structural engineer: Thornton Tomasetti Construction manager: Mortenson |

To truly understand the feats of architecture and engineering required to complete this one-of-a-kind transformation requires knowing a little history and background. The original venue was built at-grade (plaza/street level) with a capacity to host up to 13,200 spectators. The 1995 renovation lowered the event floor elevation by approximately 38 feet and added amenities, such as concession stands and club-level seating and approximately 3,000 seats. Two decades later, additional upgrades were needed to meet or exceed other NHL and NBA facilities.

THE CHALLENGE

In fall 2017, KeyArena was classified by the Seattle Landmarks Preservation Board as a local landmark. This distinction required that the Paul Thiry-designed roof, curtainwall and exterior concrete elements be preserved as part of Oak View Group’s plans for the arena.

To achieve the project goals and increase the building footprint beyond the exterior curtainwall at the plaza level, the project team not only had to dig deep below the landmarked existing roof, but it also had to dig deep into the construction playbook for solutions. Most notable among these was determining how to demolish the existing structure and excavate 680,000 cubic yards of soil to make space for a new below-grade arena, all while temporarily supporting the 400-by-400-foot historic roof structure above.

PRESERVING A LANDMARK

The ability to support the existing roof while work went on below drove nearly all facets of the project’s design and construction. The original roof was supported vertically by 20 concrete Y-shaped columns on shallow foundations spaced approximately 60 feet apart around its perimeter. The lateral loads, from seismic and wind, were resisted by a tripod of sloping concrete legs at the center of each side, serving as a buttress aligned to the roof’s steel arch truss.

TEMPORARY ROOF SUPPORT

Since the foundations supporting the existing 44 million-pound historic roof would be undermined by the excavation for the new event level, a temporary roof support (TRS) system would need to support the vast majority of the roof’s gravity load as well as resist wind and seismic lateral forces during construction. Essentially, the roof would need to temporarily float above the construction site while the excavation and construction of the new below-grade seating bowl went on below. The 3,700-ton temporary steel framing for the TRS was fabricated and installed by LeJeune Steel and Danny’s Construction, the same team that would construct the new arena. The TRS included shoring pipes that were socketed some 85 feet below existing grade to support and maintain the integrity of the roof during construction.

SHIP IN A BOTTLE

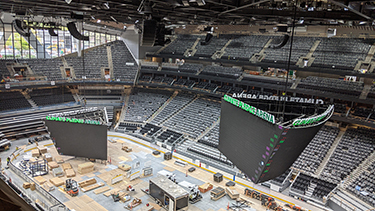

Designing and constructing a new steel-framed arena below the temporarily supported roof and around the temporary perimeter shoring was much like building a ship in a bottle. The arena, which is the first net-zero-carbon-certified venue in the world, consists of a new event level 15 feet below the existing undersized event floor elevation, four complete arena levels at and below the surrounding grade (upper concourse, suite level, main concourse and mechanical mezzanine), and two levels above the surrounding grade. All levels extend to or beyond the perimeter of the existing roof.

On the west side of the arena, a new press-level bridge floating above the seating bowl is supported by two trusses spanning 275 feet between the new steel-framed elevator cores. The elevator core towers also support the existing corner roof trusses to facilitate the removal of existing corner columns. Slide bearings were provided between the new elevator core steel and the existing roof structure to seismically isolate the roof from the new bowl structure below.

In addition to seismic retrofits to the roof, other measures included strengthening the steel roof trusses and their connections to bring them up to current code requirements and supporting the additional loading of the new structure. The roof is now able to support two 30-ton video boards along with hoisting equipment, a new catwalk, and rigging grid with 100 tons of rigging capacity to accommodate modern concert touring and award shows.

A STRONG TEAM

In sports, you need a strong team and an effective strategy to be the best. The same can be said for complex projects like Climate Pledge Arena, which necessitated an integrated approach to solving challenges. All stakeholders, including the owner, architect, engineer, construction manager, and steel contractor, provided timely input and feedback to produce innovative, practical, constructable, and cost-effective solutions.

Bringing a local landmark into the modern era is no simple task, especially when all of Seattle is watching. And while it may look familiar from the outside, make no mistake that Climate Pledge Arena is an entirely new world-class sports and entertainment venue.

Matthew Farber, PE, SE, is a principal at Thornton Tomasetti. Brian Morgen, Ph.D., PE, SE, LEED AP, is vice president and Seattle office director with Thornton Tomasetti.

Other Stories:

- Setting new marks for sustainability, innovation, fan experience

- What it took to build the ‘greenest’ arena ever

- Reimagined precinct brings back World’s Fair magic