|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Environment

| |

|

March 23, 2017

Georgia Tech wants a Living Building, but can designers beat the heat?

PAE Consulting Engineers

Brune

|

Mead

|

The Georgia Institute of Technology in Atlanta is aiming to build the world’s next Living Building, one of a handful of such buildings on a college campus.

The building will meet the high standards of the Living Building Challenge 3.1, the built environment’s most rigorous and ambitious performance standard. The LBC requires buildings to operate annually on a net-positive energy basis. This means that the building must produce 105 percent of its own energy each year.

Keeping the heat out

For Georgia Tech, designing to net-positive energy demands significant planning and design team coordination. To accomplish this, designers first prioritized cooling- and heating-load reduction options to minimize the energy needed and allow passive operation for longer periods of time.

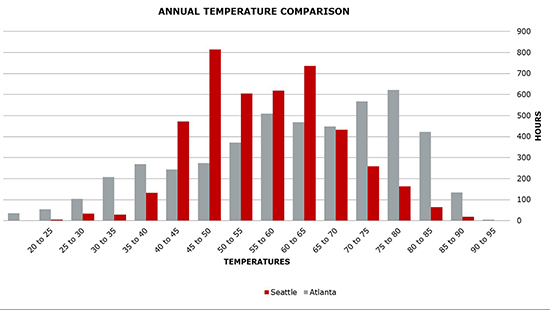

Atlanta’s climate is hotter and more humid that Seattle’s. Summer nighttime temperatures in Atlanta may not drop below 70 degrees some nights, while Seattle summer temperatures frequently drop below 60 degrees.

Designers prioritized decisions that enhanced the building’s ability to operate passively in Atlanta. This meant attention to strategies that would reduce summer cooling needs.

Particular attention was paid to reducing infiltration, the uncontrolled movement of outside air into the building. In Atlanta, infiltration brings in large amounts of hot air and humidity. To keep these out, designers considered options like extreme envelope airtightness, vestibules, rotating doors and air curtains. Exterior venetian blinds are employed on the building’s west facade to limit the cooling load from summer sunshine. Triple-paned glazing aids in winter and summer to reduce building loads. The nighttime humidity and high temperatures also meant that natural ventilation and night flush strategies were not a great option.

Reducing energy use

Because the building will rely on renewable energy it creates onsite, reducing the total energy required is critical.

Every element of the design is evaluated using the energy models managed by PAE, the project’s mechanical, electrical and plumbing designers. The models give the designers information about how much energy savings can be achieved by implementing additional energy conservation measures.

Developing an energy-use model for a project with a fixed energy goal requires a remarkable amount of intentionality and rigor, as the model ultimately determines how much photovoltaics are purchased and installed. Decisions about small operating details become crucial. Factors such as operating hours, thermostat set points and plug loads become enormously important when all power must be generated onsite.

Designers are analyzing a number of questions:

• The plans include a coffee cart to be added in the first-floor atrium and a maker space with significant power demand. Can the project accommodate the energy that would require?

• The LBC requires all potable water be generated onsite. How much energy will onsite water treatment strategies require?

• How many laptops, tablets and phones are likely to be charged at convenience outlets on a typical day?

• Would students use or bypass rotating doors intended to keep heat and humidity out of the building?

Indoor comfort

In order to make sure occupants experience thermal comfort with minimal energy use, strategies include radiant heating and cooling floors, dehumidification air handlers, and a closed-loop geothermal heat pump system.

Radiant cooling is unusual in humid climates because of condensation concerns on the cold radiant surface. Designers are including additional condensations sensors and temperature reset strategies to mitigate the risks.

The dehumidification air handlers being considered include dual-heat recovery wheels; one wheel provides heat recovery from the exhaust air, while the other provides free reheat. The net effect of the system is an approximately 30 percent reduction in the energy needed for dehumidification.

The building’s primary heating and cooling source will be 50 350-foot-deep geothermal heat pump bores. The heat pump system increases efficiency over a more common air-source heat pump by exchanging heat with the ground, which is a constant 60 degrees in Atlanta.

Finally, the team is designing to a more expansive theory of thermal comfort than typical. Thermal comfort is defined by six primary factors: air temperature, radiant temperature, humidity, air speed, clothing level and activity level.

All six variables are being considered in the design. The end result is a building operating at higher air temperatures in summer without sacrificing occupant comfort. This reduces energy use and the size of the mechanical system that needs to be installed.

Onsite energy

After these energy-efficiency measures are included, onsite renewable energy is added to the building to balance the energy requirements.

The project’s current predicted Energy Use Intensity is around 30 kilo-British thermal units per square foot annually. That requires approximately 17,000 square feet of solar photovoltaic panels to meet the predicted demand of the building.

The rooftop photovoltaic array will multitask by producing energy, collecting rainwater and providing shade for the south and west facades. Onsite battery storage is included to provide a backup option in the case of a prolonged power outage.

A model for others

Building to net-positive energy leads to different design decisions with added benefits: Extra daylight improves occupants’ natural circadian rhythms, engaging the environment adds to the site’s natural beauty, and putting energy-saving systems on display educates occupants.

The building will be a showcase for sustainable practices, and a healthy and positive addition to the environment. The hope is that the project will ultimately be replicable and a model that other universities and campuses around the world can look to for their own Living Buildings.

Funded through a private grant from The Kendeda Fund, the Living Building at Georgia Tech is expected to become a Living Building Challenge 3.1-certified facility in 2019. The project’s design and build partners include architects Lord Aeck Sargent in collaboration with The Miller Hull Partnership and construction manager Skanska. Design team consultants include Newcomb & Boyd, PAE Consulting Engineers, Uzun + Case, Biohabitats, Andropogon and Long Engineering.

Marc Brune is an associate principal and David Mead is a building performance specialist at PAE Consulting Engineers.

Other Stories:

- 2 state bills would reward owners who green up their buildings

- How 'negawatts' help the building industry fight climate change

- Next frontier for sustainability? The people inside all those green buildings

- 4 strategies to make office workers healthier and more productive

- ‘Biophilic’ design bonds children with nature

- Eco-friendly transfer station adds playground to be a good neighbor

- Sweat the details to make building green pay off

- 12 Bel-Red townhouses help restore a trashed site