|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

April 28, 2011

Don’t rely on computers to get steel detailing right

Special to the Journal

Olsen

|

Steel detailing is the craft of transforming the information found in contract documents into drawings that the steel fabrication shop can build to.

Every steel-framed project requires the work of a steel detailer. In addition to the shop detail drawings, the steel detailer creates the erection drawings that show where all the parts and pieces go for the steel erector who puts it all together in the field.

The introduction and advancement of steel detailing modeling programs has made work easier for steel detailers. This process of detailing steel using a computer program saves the labor of drawing individual pictures, though the steel detailer still needs to format and edit the pictures of the parts on the drawing sheets according to industry standards.

When the program is used correctly, the result will be accurate shop detail and erection drawings. If the information given by the model is incorrectly shown on the drawings, the result will be virtual garbage — even if the dimensions are correct.

Drawings that are not industry standard will cause difficulty for the designers, slowing down the approval review time. If the details are not shown as expected by the fabricator and erector, the steel will be fabricated less efficiently and incorrectly, causing the steel not to fit in the field.

To avoid such difficulties, reputable steel detailing firms will have a detailing checker review the completed drawings for accuracy and compliance with industry standards prior to approval. Less experienced detailing firms feel additional checking is not necessary because a modeling program has been used in the creation of the drawings. The time and money saved could then be passed on to their customers. Offering lower prices would then mean they could get more work.

This “economy” in purchasing steel detail drawings that have been produced in this way translates into extra work for all the other trades down the line, an expense that is impossible to quantify. But it is an expense that would be avoided if the drawings were checked for industry standards during the approval process.

“Train wreck” project

The topic of steel fabrication economics was discussed with colleges regarding a project that was subcontracted to an offshore steel detailing firm. Steel fabricators were very busy at the time that this project was built, and most steel detailing firms were unable to take on a project without overtime costs.

The steel fabricator was approached by an offshore steel detailing company who was interested in taking on the job immediately at 10 percent of the current market value.

This offer was very attractive so the steel fabricator subcontracted the work to this company with which it had no prior working experience. The steel fabricator believed that the work would be completed accurately and in a timely manner because the steel drawings were to be created with a computer modeling program.

The ramifications of what the steel fabricator thought was a good buy in steel detailing quickly resulted in a train wreck of a project.

The steel fabricator had many years of fabrication experience, but wasn’t savvy with regard to steel detailing.

Not only had the steel fabricator decided that an offshore detailer using a modeling program was the answer to its budget and scheduling woes, it also didn’t feel the need to review the shop drawings for quality and accuracy. The fabricator believed that the shop drawings, once approved by the general contractor and the designers, would be perfect and ready for fabrication.

It became clear upon reviewing the shop detail drawings that the steel detailing employees who edited them had little knowledge about how the pertinent information should be shown for the steel fabricator and the steel erector. The steel detailing firm was clearly trying to use the computer modeling program to replace experienced steel detailers. The shop detail and erection drawings created were amateurish and difficult to follow.

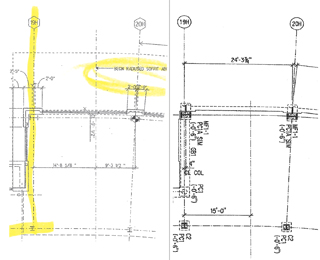

The steel detailer had drawn the steel backwards to normal reading standards — from right to left instead of left to right. Beams were detailed at the wrong length and columns at the wrong height. The roof placement plan in this single-story building bore no dimensions; no column marks, no shear tab marks on the columns and beams, and the piece marks were not located correctly for the erector.

In order for the steel to fit in the field, holes were slotted, new connections were made, and beams were shortened or lengthened. As a result, the erection schedule fell months behind.

Fabrication errors and the resulting problematic steel erection created scheduling delays that forced the general contractor to replace the original steel fabricator.

The new fabricator had to have the steel detailed by a different firm, for it was determined that the model created by the original fabricator’s steel detailer was not usable.

Preventing problems

The original steel fabricator was headed for trouble when it subcontracted to an unknown steel detailer because of the low price, and without verifying work experience and quality.

What is the best solution to prevent problem projects like this one?

To find the answer, we need to first find the root cause of the problem. Let’s go back to the beginning.

The first task for the steel detailer is to find the correct locations of the building columns. If dimensions are missing or are difficult to interpret, an experienced steel detailer would have sent a request for information (RFI) to the steel fabricator to establish the correct dimensions for locating the centerline of the columns.

The original steel detailer for this project made its own assumption about the dimensions, completed its drawings and sent them out for approval, believing that if its assumption was not correct, the drawings would be corrected by the approvers. But the drawings came back from approval without the expected verification.

It is not the job of the designers to verify the dimensions that are on the steel shop drawings. The approvers know that the dimensions shown on the steel shop drawings are for steel fabrication purposes, and may not match with dimensions shown on the design drawings.

For the designer to answer verifications correctly, it needs to know why the question is being asked. This is why RFIs are used; to get the correct answers to specific questions.

Had an RFI been sent for verification of dimensions relative to the missing information prior to developing the shop drawings, it would have created a whole different outcome on this project. As it was, the bust in the design drawing dimensions was never resolved, and served as the beginning of all the resulting problems on the project.

The only solution to problems like these is in the prevention of them. The path to that prevention is to have the completed design drawings reviewed by someone who has working knowledge of them prior to their release for bid.

What do we mean by “working knowledge”?

Working knowledge of the drawings is the ability to read the design drawings and to interpret that information into what the steel professionals need to be able to do their job.

When a workability review is performed by someone with a working knowledge of the design drawings, the gap between the designer’s intent and the steel shop drawings is then bridged at the design level. The need for addendums, RFIs and change orders would be minimized or eliminated. The savings in cost and time for the designers, contractors and subcontractors would be unquantifiable.

Had a workability review been done on this project, much, if not all, of what happened would have been avoided. Workability reviews prevent projects from turning into cost-accounting and scheduling nightmares.

It is the quality of the work we all do for the project that determines the productivity and efficiency of getting the building built. Low price should not be the only deciding factor in choosing our contractors and subcontractors. Saving money and time in the building schedule by way of accuracy and efficiency should be.

Kerri Olsen is a steel professional, technical writer and author who recently released “The Art and Science of Steel Estimating — Beginning Fundamentals,” a comprehensive guide for the steel novice.

Other Stories:

- Contractors must adapt or be left in the dust

- Follow these 10 steps before signing a contract

- Time to change your perception of alternative energy

- 6 factors affect today’s bid prices

- 10 ways to cut construction fuel costs

- Public agencies warm up to design-build projects

- What’s in your construction contract?

- More federal contracting jobs await women

- Stack removal was a tall task