|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

May 9, 2017

Cast-in-place structures: Parking garage

Special applications: Technical merit (tie)

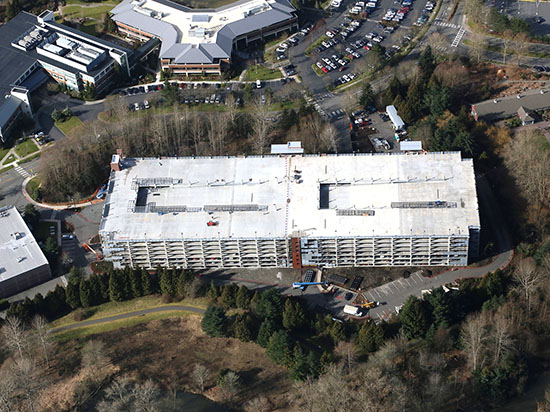

Costco Wholesale parking garage

Location: Issaquah

Owner/developer: Costco Wholesale Corp.

Team: Ferguson Construction, general and concrete contractor; MG2, architect; Engineers Northwest, structural engineer; Cadman, ready-mix supplier

Hidden among the trees next to Pickering Barn on the Costco Wholesale corporate campus in Issaquah sits a new eight-level, post-tensioned concrete parking garage. The garage has 2,575 stalls and used over 26,000 cubic yards of ready-mixed concrete.

The new garage sits on 528 16-inch-diameter, concrete-filled steel piles averaging 100 feet in depth.

Originally the garage was designed for seven levels, with five to be construcQted in 2014 and two in a future expansion. After the completion of level five, the decision was made to increase the garage from seven levels to eight. This created a unique structural challenge, as the foundation was only designed to support the original seven levels.

What makes the project unique from other parking garages is the use of lightweight post-tensioned concrete. By changing the top three decks from a traditional 6,000-psi concrete to lightweight concrete, the weight was reduced from 150 pounds per cubic foot to 118 pounds.

A great concern in incorporating lightweight concrete was the ability to make early strengths for stressing in order to maintain schedule. In addition, there were concerns for pumping over great distances as well as the finishability with porous aggregate.

Cadman delivered over 7,400 cubic yards of lightweight concrete without any issues. The performance and engineering of the mix design exceeded all expectations.

Strengths exceeded the 3,000-psi requirement at three days, allowing for an early two-day stress, improving the overall stressing schedule. Improving on the schedule was especially important given that the parking levels below the top decks were occupied during construction.

Twenty-eight-day strengths averaged over 7,700 psi. The lightweight design pumped, placed and finished with ease.

The aggregate used was expanded shale from Colorado. It is believed this may be the first post-tensioned lightweight structure on the West Coast.

Other Stories:

- Grand Award

Public works: Bridges - Special applications: Resiliency

- Community Award

- Concrete paving

- Pervious concrete

- Artistic and decorative concrete

- Residential concrete

- Public works: Renovations

- Public Works: Infrastructure

Sustainable Merit - Cast-in-place structures

- Tilt-up structures

- Special applications: Technical merit (tie)