|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

February 27, 2020

Building out this new hybrid OR was no simple operation

PCS Structural Solutions

Parke

|

Rapidly evolving health care technology requires sophisticated facilities and infrastructure. Likewise, the rigorous demands of these specialized designs require high-performance collaboration teams.

So when University of Washington Medicine needed to upgrade a critical operating room, they partnered with a capable design-build team to design and construct a highly technical hybrid bi-plane operating room, one of only a handful of such facilities nationwide.

Hybrid operating rooms

Hybrid bi-plane operating rooms are surgical suites that provide real-time patient imaging data — in this case a C-shaped biplanar imaging system that generates images on two separate planes — and allow a quick shift from diagnosis to surgical treatment in the same room. Hybrid operating rooms are sized and configured to exacting specifications. The rooms must support cardio- and neuro-medical teams, among others, and roughly 15,000 pounds of equipment.

At Harborview Medical Center, the new systems were integrated into an existing operating room. Every wall, ceiling and floor of a medical facility is jam-packed with programming — ductwork, conduit, lighting, medical gases, monitors, booms, storage, and structure. How to add more programming to an existing room is a highly complex orchestration that requires the design-build team to find truly unique solutions on a tight schedule and with minimal impact to hospital operations.

Team vision

We knew that designing a hybrid operating room required robust teamwork. Solid design solutions would develop from effective communication and coordination of large amounts of information.

Because PCS goes all in on medical projects, from billion-dollar patient towers to cutting-edge operating room replacements, the Harborview project was a natural fit. Preparing for project pursuit, the design-build team held meetings to cement the cohesiveness and camaraderie the project would need throughout design and construction.

Even before work began, we invested the time we needed to build authentic connection and to develop a team vision for the project. Each team member selected an image they felt best fit their role and desires for the project. For example, PCS saw our role as an iceberg — even though the structural engineering would be hidden inside the walls, it needed to have a huge impact.

Design-build

Design-build delivery provided the project with an essential framework: early collaboration, teamwork, efficiency and speed. It was critical that the project go seamlessly from design to build and limit impact to a busy operating floor. Open and free communication between contractor, architect and structural engineer early in the design process was crucial.

The design team and the subcontractors who were engaged early in the process worked together to help interview and select several specialty subcontractors, including the integrated ceiling specialist, which was pivotal to the success of the team.

End-user participation brought the real-life operating room experience and informed fundamental decisions. The design team created hand-adjustable models of the operating room.

Moving the pieces, the physician teams communicated precisely what operating room functionality needed to look like and why. The surgeons and hospital staff helped establish the control-room and viewing window locations and bed orientations.

Operating room nursing staff knew where in-room storage had to be situated and what could be located outside the room. The anesthesiology crew also needed operating room real estate.

Having the contractor as a partner from day one allowed the entire design team to take what we learned from each end-user meeting, walk directly over to the space and coordinate design solutions. It was because of this thorough coordination that the project achieved no structural comments under a stringent review from the city of Seattle. With the tight schedule and need for early input, design-build delivery greatly minimized both schedule and budget risk.

Structural design

Well-orchestrated pull planning was critical to getting all the pieces in the right place at the right time — coordinating timely installation of steel in preparation for the prefabricated integrated ceiling, for example.

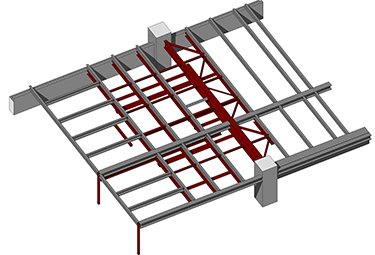

The team had to decide whether to replace or strengthen the mezzanine floor above the operating room to support the new integrated ceiling booms and imaging arm. Through close coordination with the general contractor, Aldrich + Associates, the decision was made to strengthen and stiffen the existing steel mezzanine, first to minimize demolition and also for ease of moving steel framing material though an active hospital.

When suspending multiple booms, ceiling lights and an imaging arm, seismic bracing and stability were paramount. Rather than using traditional braces which would create more obstructions in the busy mezzanine space above, the PCS team created a horizontal truss out of the existing mezzanine.

With the simple addition of small steel shapes, the ceiling and equipment were braced leaving enough space for the placement of ducts and piping, etc., by the mechanical and electrical teams.

Columns were eliminated and moved to free the operating room of obstructions, yet structural depths were precise to allow the operating room to be built within a 13-foot-6-inch floor-to-floor space. Because 30-foot steel beams couldn’t be carried up the elevator, they were brought up in pieces, connected and lifted into place like a ship in a bottle.

Construction is currently wrapping up, completed in just over six months, in one of the busiest operating room spaces at Harborview Medical Center. With little downtime to adjacent operating space, minimal field issues, attention to budget and an expedited schedule, the owner is being delivered a high standard of care.

The new hybrid bi-plane operating room will help physician teams provide leading-edge health care to patients in the region and stand ready to embrace emerging VR and AI technologies. It is poised to attract health care talent to the area who will continue to innovate health care practices.

The Harborview hybrid bi-plane success demonstrates how early collaboration can meet the needs of a project with breathtaking complexity and rigorous requirements.

Todd Parke is an associate principal at PCS Structural Solutions.

Other Stories:

- Hospital projects in rural areas face extra obstacles

- UW’s new health sciences building will be a hub for 21st-century care

- Good design takes some stress out of visiting the hospital

- Hospitals giving way to other care options as providers look to cut costs

- CHP systems: a powerful energy-saving tool for hospitals

- A look inside the Cure Factory, Seattle Children’s new cell therapy lab

- Fire dampers: one more way hospitals can save lives

- Integrated project delivery offers risks and rewards for team members

- Health care could look a lot different in 2040, so get ready

- Here’s what’s in store for health care in the Northwest

- How welcoming design can improve outcomes for patients — and staff