|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Construction

| |

|

October 6, 2022

Teamwork creates modern, flexible spaces to learn

Special to the Journal

Howard

|

Gunn

|

McCann

|

At the Health Sciences Education Building, a newly completed 97,000-square-foot learning space on the University of Washington campus, the design-build team of Lease Crutcher Lewis, The Miller Hull Partnership and SLAM partnered to deliver a health education facility that pairs flexible spaces with modern technologies to enable interdisciplinary and team-based learning for future health care professionals.

The team was tasked with maximizing the building program and finding a way to integrate cross-laminated timber (CLT) into the design and construction. At the project’s onset, the university’s Project Delivery Group asked, “Is there any reason this building can’t be CLT?”

The answer was not simple. Too many variables factored into it — from program to cost, to building performance — and no single team member had the full answer. This is where the valuable collaboration and problem-solving afforded by progressive design-build came to fruition. To provide the UW with an answer, the design-build team brought all the project partners in a room — from KPFF to Structurlam, to Miller Hull and Lewis — to run numbers, discuss challenges and find a solution that met program, schedule and budget needs.

BUILDING PROGRAM

During project definition, the team dug into the details and recognized that a full mass timber structure would require too many columns, prohibiting open collaboration and flexible classroom spaces — a critical component of the intended program.

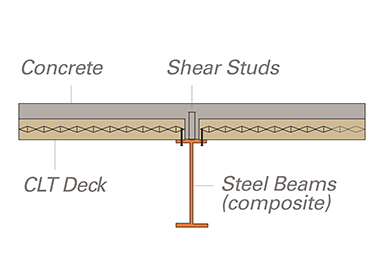

Led by KPFF, the design-build team identified a new hybrid system, which incorporates long 53-foot spans of steel beams, topped by a CLT panel and a finished concrete topping slab. The system harnesses the long spans afforded by steel beams, allowing for enhanced program flexibility and future uses.

PROVING THE SOLUTION

A hybrid structural system like this is undefined by the building code, so before the team could begin design and construction, it needed to research and test the system to prove it was a viable option.

Lewis, Miller Hull and KPFF partnered with university faculty, staff, and graduate students to design, procure, install and test a series of composite panels inside the university’s structural engineering laboratory. Not only did this provide the information required to advance the project from a code standpoint, but the testing also provided an invaluable opportunity for UW students to participate in practical applications of theory and research, learn first-hand from tradespeople how work is executed, and tangibly contribute to the development of the campus around them.

A portion of the testing was funded by a Wood Innovations Grant from the U.S. Forest Service to study the floor vibration of CLT panels. These test results will be published to help engineers optimize the design of future CLT buildings, helping to make CLT a more viable and cost competitive structural system.

APPROVAL AND LOGISTICS

Progressive design-build compresses the overall project duration, and the CLT permit approval was uncertain, so the team had to remain flexible. The team designed a structural system that could accept either steel decking or the CLT hybrid system depending on the results of the performance testing. Once the permit was approved, the team could immediately order CLT to place on-site. Since Structurlam was an integral part of the planning and decision process, it could fulfill the order and keep the project progressing quickly.

With a new structural system comes new challenges and opportunities to establish best practices. The project team proactively engaged industry experts and associations to understand concerns that accompanied the use of CLT panels in this application, then supplemented this feedback with expert knowledge to develop mitigations for each challenge.

The team worked with Structurlam and MEPF partners to identify and cut hole penetrations at the factory — ensuring consistency and quality while shortening the installation time. Moisture protection measures, hoisting methods and steel bearing tolerances were coordinated by the entire team prior to delivery and installation. The detailed coordination meant the team could beat production rates — placing each 20,000-square-foot deck in 1.5 to 2 days — and incorporate $65,000 of value back into the project.

The challenging structural components at the Health Sciences Education Building are a prime example of the importance of team collaboration and mutual trust, as well as the value design-build brings to complex projects. When a team is aligned around a common goal with the right experts in the room to make decisions, innovative solutions are born.

The Health Sciences design-build team rallied around the university’s goals for CLT use in its building to find an innovative hybrid CLT solution that meets program and budget needs while complementing the biophilic design of the building. As we continue to push boundaries and solve complex problems, it is in our best interest to do so as a shared team.

Duncan Howard is a project manager at Lease Crutcher Lewis; Jacob McCann is a principal at KPFF Consulting Engineers; and Bradly Gunn is a project architect at Miller Hull Partnership.

Other Stories:

- Design can influence beyond its borders

- The next great environment for schools

- K-12 alternative delivery is here to stay

- Here’s how to decrease carbon emissions in schools

- Feasibility and design in early learning education

- Designing a co-location campus

- Centering community for a transformational result

- Building resiliency at University of Washington