|

Subscribe / Renew |

|

|

Contact Us |

|

| ► Subscribe to our Free Weekly Newsletter | |

| home | Welcome, sign in or click here to subscribe. | login |

Architecture & Engineering

| |

|

October 3, 2019

With so many tech advances, why has AEC productivity growth stalled?

Cary Kopczynski & Co.

|

Technology will provide the missing link for improving productivity in the design and construction industry.

Or will it?

As everyone knows, there have been incredible — almost unbelievable — advancements in technology in recent years. There was a time when all phones were attached to a cord that was attached to a wall. The rotary dial had to be spun. Visual voicemail had not even been thought of, since there was no screen to view the message.

Fast-forward to today. Many people reading this article are doing so from a portable, high-resolution color screen attached to a device that can provide services to help them in all aspects of their daily lives.

If technology has advanced so far, why is it that in the last 50 years — the same period that has seen the phone go from rotary dials to portable smartphones — productivity growth in the design and construction industry has flatlined? Surely with all this technology there must be a significant construction productivity benefit.

But statistics show that for the past five decades, productivity in the overall design and construction industry has actually declined slightly, according to Paul Teicholz, professor emeritus of civil engineering at Stanford University.

The advent of the modern computer age has caused every industry to rethink and reinvent the way it does business. This includes the world of design and construction. Nevertheless, for every step forward in construction productivity, statistics show that there has been an equal step backward.

I don’t have sufficient insight into the field productivity side of this problem to offer informed comment. As a practicing design engineer, however, the causes of productivity snags seem quite apparent. In a nutshell, there needs to be a rethinking of our design methodology and work product to allow the full potential of today’s technology to be realized.

Inefficient processes

With the advent of the computer and instant communication, many people changed their primary communication style from talking in person to emailing and texting. Businesses also changed. They eliminated the jobs of stenographers and others, and threw out carbon paper. File cabinets gave way to hard drives and local networks.

In short, as technology advanced, businesses and consumers advanced with it, changing their production procedures and work product to suit the new ways of producing and delivering goods and services. However, at least in the world of design, our industry has not updated fundamental ways of doing business to allow the full realization of the technological power available to us.

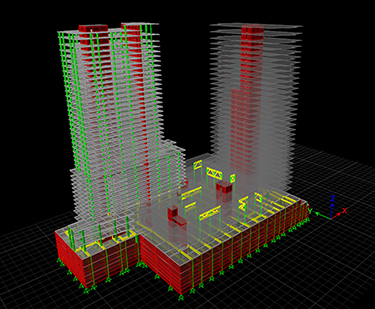

Some parts of our industry have done better than others. BIM modeling, for example, is perhaps one of our most “game changing” recent advancements. Nevertheless, overall productivity growth in our industry — including design — continues to flatline. Perhaps one of the areas most ripe for change is the design process itself.

Architects spend hundreds of hours producing digital models of their buildings in advanced 3D BIM software, only to print the plans in 2D and send them to the structural engineer for review. The engineer then designs the structural portions of the building, typically utilizing 3D analytical software to more accurately determine the effects of forces on the structure. He or she then gives the design to drafters to make a 3D BIM model, to then print out 2D plans and send back to the architect.

Certainly, architects will sometimes send their 3D BIM models to the engineers, and vice versa. The actual design work is often done using 2D plans, however. Not the 3D model.

The fundamental idea of the 3D model is for complete integration and coordination of all portions of the building — the goal is to build the complete building digitally before constructing it in the field. And yet, since both engineer and architect often make separate models and coordinate largely through 2D plans, the potential benefits of collaboration, coordination and clash detection are almost completely lost. This causes a significant loss in efficiency, which is compounded by the fact that 3D models are often more time consuming to prepare than 2D plans.

Compatibility issues

Structural design efficiency can also suffer in other ways. The 3D BIM model rarely helps the structural engineer with his calculation package since it is seldom transferred to the structural analytical software. When it is, there is often significant time spent “fixing” it to create compatibility between the BIM model and the analysis package so that the analysis software, which is separate from the modeling software, can work properly. For this reason, it is usually more cost effective to draft a 3D model of the building after the basic components have been designed.

One of the biggest issues with these software packages is that most of them specialize in different parts of the structure. The engineer is left to design the gravity system with one software package, the lateral system with another, and the foundation with a third — each time transferring the loads from one software to the next “by hand” through spreadsheets.

The specific components are then broken out further into different software packages, to then be designed separately. In a perfect world this happens only once.

Most building designs change multiple times before they are constructed, however. When these changes occur, this process of designing individually through a chain of software packages must be repeated.

Encouraging developments

The good news is that positive changes are occurring and, going forward, encouraging strategies are being pursued.

One is to form a standard format of input and output that works for all software, by which the engineer can update the entire design by altering the changed components in one location. Preferably, this will occur in the 3D modeling software, which will then automatically trigger coordination by the analytical software.

Another is to create single and more comprehensive analytical software packages that handle the entire design. These two changes and others will help structural designers in important and significant ways.

The realization of these objectives is still a ways out, however, leaving the structural designer of today’s buildings to sometimes question whether it is faster and more efficient to design everything “by hand” with specialized spreadsheets.

Perhaps if the design and construction industry chose to fully embrace today’s available technology, further technological advancements would occur to support those choices. When the smartphone industry exploded into a market worth billions, it triggered massive improvements in smartphone technology. Perhaps when the construction industry fully incorporates the tools currently available, it will trigger similar advancements to the benefit of all.

Sam Dougherty is a design engineer with Cary Kopczynski & Co.

Other Stories:

- Why electric scooters could be a game changer for Seattle

- CLT: construction’s lean, green beauty queen

- The AEC industry has a data problem

- What our evolving mobility options mean for designers and developers

- New OSU-Cascades academic building will aim for net zero

- Mass timber is bringing the warmth of wood to the workplace

- Survey: Cary Kopczynski & Co.

- Survey: Weber Thompson

- Survey: Johnston Architects

- Survey: Bohlin Cywinski Jackson

- These 3 Northwest projects show how listening to clients pays off

- Which project delivery methods work best?

- How understanding building codes can help you get more out of your project

- How successful workplaces offer more than just a place to work